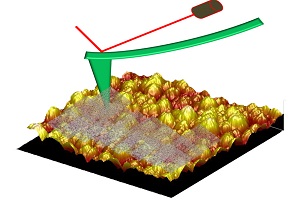

力曲线用于硅负极材料表面膜的研究

收稿日期: 2013-05-27

修回日期: 2013-07-15

网络出版日期: 2013-12-23

基金资助

中科院知识创新工程重要方向项目(No. KJCX2-YW-W26)、国家重点基础研究发展计划(973)项目(No. 2012CB932900)资助.

An Investigation on the Solid Electrolyte Interphase of Silicon Anode for Li-Ion Batteries through Force Curve Method

Received date: 2013-05-27

Revised date: 2013-07-15

Online published: 2013-12-23

郑杰允 , 郑浩 , 汪锐 , 李泓 , 陈立泉 . 力曲线用于硅负极材料表面膜的研究[J]. 电化学, 2013 , 19(6) : 530 -536 . DOI: 10.13208/j.electrochem.130357

/

| 〈 |

|

〉 |