FeCo合金纳米电催化剂制备及其性能研究

收稿日期: 2012-04-17

修回日期: 2012-05-03

网络出版日期: 2012-05-04

基金资助

新世纪优秀人才支持计划(No. NCET-10-0715),高等学校全国优秀博士学位论文作者专项资金(No. 201126)和浙江省重中之重学科开放基金项目(No. 20090503)资助

Preparation and Catalytic Properties of FeCo Alloy Nanocatalyst

Received date: 2012-04-17

Revised date: 2012-05-03

Online published: 2012-05-04

李明轩 , 欧洁连 , 陈声培 , 王鹏 , 许斌斌 , 孙世刚 . FeCo合金纳米电催化剂制备及其性能研究[J]. 电化学, 2013 , 19(2) : 125 -129 . DOI: 10.61558/2993-074X.3366

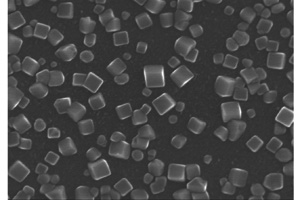

Key words: FeCo alloy; cube; electrocatalysis; nitrite reduction; oxygen reduction reaction

/

| 〈 |

|

〉 |