锂离子电池碳包覆锡负极性能研究

Properties of Carbon Coated Tin Negative Electrode for Lithium-ion Battery

Received date: 2012-01-09

Revised date: 2012-02-09

Online published: 2012-03-09

申晓晓 , 刘贵昌 , 王立达 . 锂离子电池碳包覆锡负极性能研究[J]. 电化学, 2013 , 19(2) : 169 -173 . DOI: 10.61558/2993-074X.2946

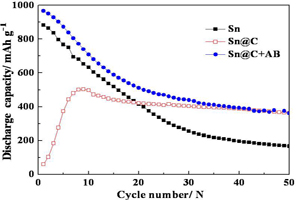

Key words: lithium-ion battery; carbon coating; tin; cycle performance

/

| 〈 |

|

〉 |