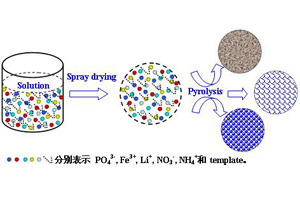

采用有机物辅助模板剂,经喷雾干燥制得LiFePO4/C复合正极材料,考察了不同模板剂对材料的形貌和性能的影响。采用X射线衍射 (XRD)、扫描电镜(SEM)表征与观察样品,采用交流阻抗(EIS)、循环伏安(CV)和恒电流充放电测试电极性能。结果表明:样品形貌和结构可通过添加不同有机模板剂来调变,无模板剂时得到的样品是光滑实心球,聚乙烯醇(PVA)、柠檬酸和葡萄糖有机模板机可制得纳米颗粒团聚成的均匀微米球形、多孔球形和鸟巢状样品。其中以PVA为辅助模板剂制得的LiFePO4/C电极,其电荷转移电阻和比容量都较最优异。该样品在0.1 C和5 C倍率下放电比容量分别达156.7和92.1 mAh g-1,并呈现出的大倍率充放电平台及优良的倍率循环性能。

刘全兵

,

蒋阳梅

,

宋慧宇

,

廖世军

. 有机模板剂辅助喷雾干燥法制备LiFePO4/C正极材料及其电化学性能研究[J]. 电化学, 2012

, 18(1)

: 18

-23

.

DOI: 10.61558/2993-074X.2874

In this work, the LiFePO4/C composites were prepared by the spray drying and carbothermal method, and were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS), and galvanostatic charge-discharge measurements. The effects of the organic assisted templates on the morphologies and electrochemical properties of the LiFePO4/C composites were investigated. The results showed that the morphology and microstructure of the composites could be tuned by incorporating with the different templates. The morphology of the composite appeared to be solid microspheres if no organic template was added, while porous microspheres, nest-like aggregation, and uniform nano-micro spheres, if citric acid, glucose, and PVA were used as the templates, respectively. Among all the samples, the composite prepared with PVA as a template also exhibited the best properties in batteries, including the highest tap density, the lowest charge transfer resistances and the highest capacities. The best discharge capacities were measured to be 156.7 and 92.1 mAh?g–1 at 0.1 and 5.0 C rate, respectively. The obvious charge-discharge plateaus at high rates and excellent cycling performance at various rates were achieved.