基于电化学-热-力耦合模型的快速充电下锂离子电池的老化特性分析

收稿日期: 2024-02-06

修回日期: 2024-04-04

录用日期: 2024-05-05

网络出版日期: 2024-05-09

Aging Characteristics of Lithium-Ion Battery under Fast Charging Based on Electrochemical-Thermal-Mechanical Coupling Model

Received date: 2024-02-06

Revised date: 2024-04-04

Accepted date: 2024-05-05

Online published: 2024-05-09

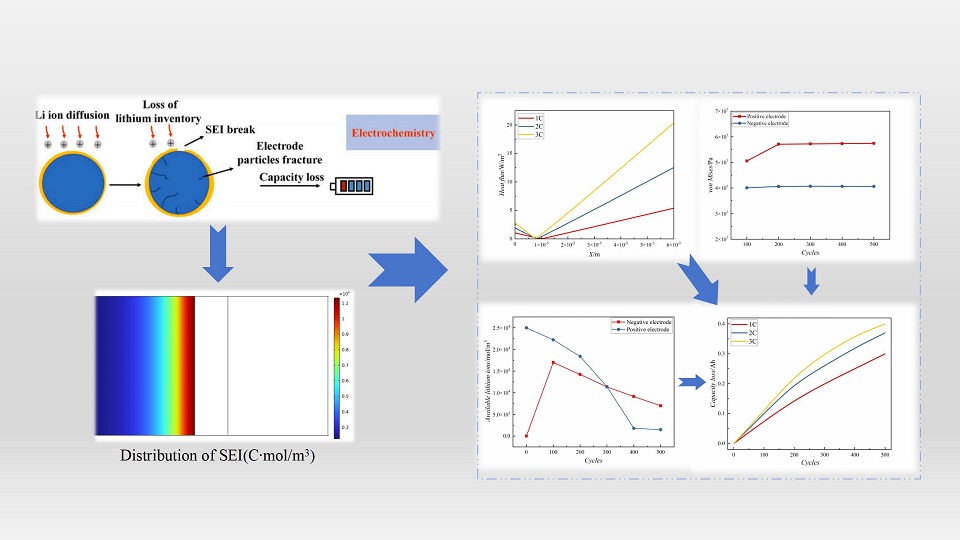

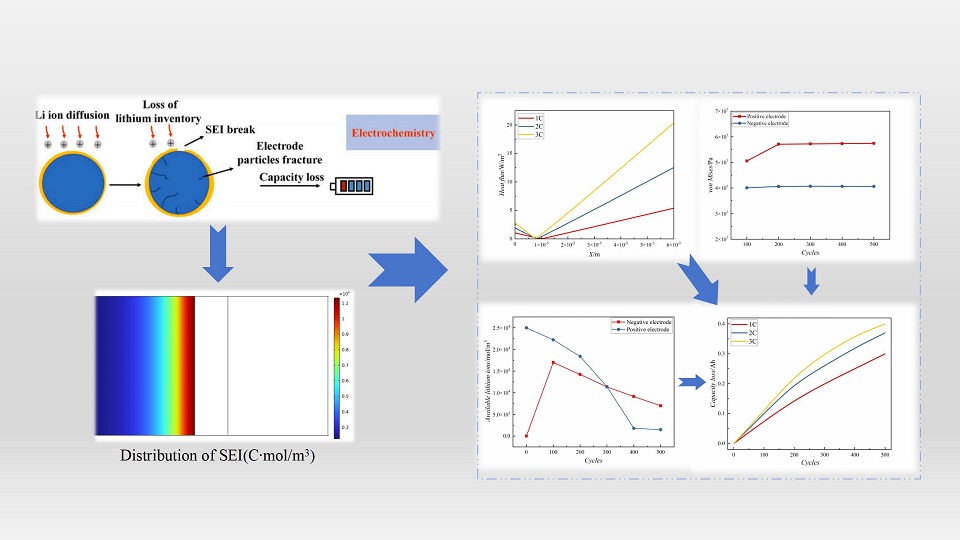

本文基于电化学-热-力(ETM)耦合模型,对快速充电下锂离子电池(LIB)的老化特性进行了数值研究。首先,通过COMSOL Multiphysics建立并求解了ETM耦合模型。随后,对电池进行了长循环测试,以探索LIB的老化特性。具体而言,从SEI的非均匀分布、SEI生长、热稳定性和应力特性等方面分析了充放电倍率和循环次数的增加对电池老化的影响。结果表明,充放电倍率和循环的增加导致SEI不均匀程度的增加,以及因SEI生成所造成的电池容量损失也随之增加。同时充放电倍率和循环数的增加也分别导致电池的发热量增加和散热率降低,从而使得电极材料热稳定性下降。此外,随着循环的进行,正极材料的von Mises应力高于负极材料,正极材料表现为拉伸变形,负极材料表现为压缩变形,正极的有效锂离子浓度低于负极的有效锂离子浓度,证明了电池正极材料在长循环下所发生的拉伸型断裂主导了容量损失过程。上述研究有助于研究人员进一步探索锂离子电池在快速充电条件下的老化行为,并采取相应的预防措施。

关键词: 锂离子电池; 老化特性; 快充; 电化学-热-力耦合模型

左东旭 , 李培超 . 基于电化学-热-力耦合模型的快速充电下锂离子电池的老化特性分析[J]. 电化学, 2024 , 30(9) : 2402061 . DOI: 10.61558/2993-074X.3468

The aging characteristics of lithium-ion battery (LIB) under fast charging is investigated based on an electrochemical-thermal-mechanical (ETM) coupling model. Firstly, the ETM coupling model is established by COMSOL Multiphysics. Subsequently, a long cycle test was conducted to explore the aging characteristics of LIB. Specifically, the effects of charging (C) rate and cycle number on battery aging are analyzed in terms of nonuniform distribution of solid electrolyte interface (SEI), SEI formation, thermal stability and stress characteristics. The results indicate that the increases in C rate and cycling led to an increase in the degree of nonuniform distribution of SEI, and thus a consequent increase in the capacity loss due to the SEI formation. Meanwhile, the increases in C rate and cycle number also led to an increase in the heat generation and a decrease in the heat dissipation rate of the battery, respectively, which result in a decrease in the thermal stability of the electrode materials. In addition, the von Mises stress of the positive electrode material is higher than that of the negative electrode material as the cycling proceeds, with the positive electrode material exhibiting tensile deformation and the negative electrode material exhibiting compressive deformation. The available lithium ion concentration of the positive electrode is lower than that of the negative electrode, proving that the tensile-type fracture occurring in the positive material under long cycling dominated the capacity loss process. The aforementioned studies are helpful for researchers to further explore the aging behavior of LIB under fast charging and take corresponding preventive measures.

/

| 〈 |

|

〉 |