以掺氢天然气为燃料直接内重整固体氧化物电池堆的稳定性

收稿日期: 2023-08-15

修回日期: 2023-10-20

录用日期: 2023-10-31

网络出版日期: 2023-11-15

Stability of a Solid Oxide Cell Stack under Direct Internal-Reforming of Hydrogen-Blended Methane

Received date: 2023-08-15

Revised date: 2023-10-20

Accepted date: 2023-10-31

Online published: 2023-11-15

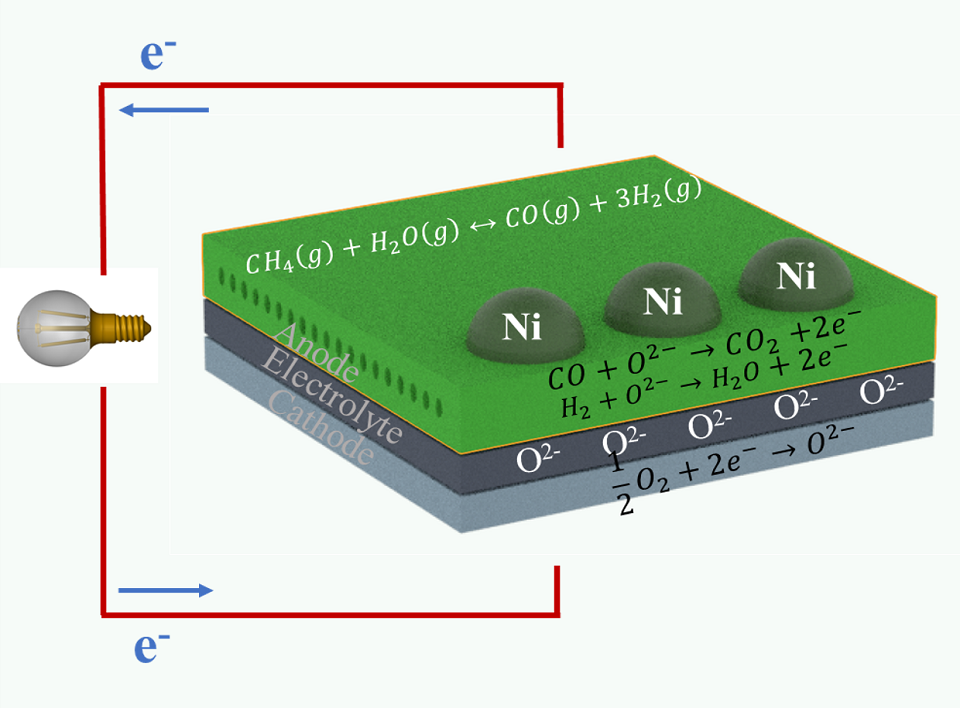

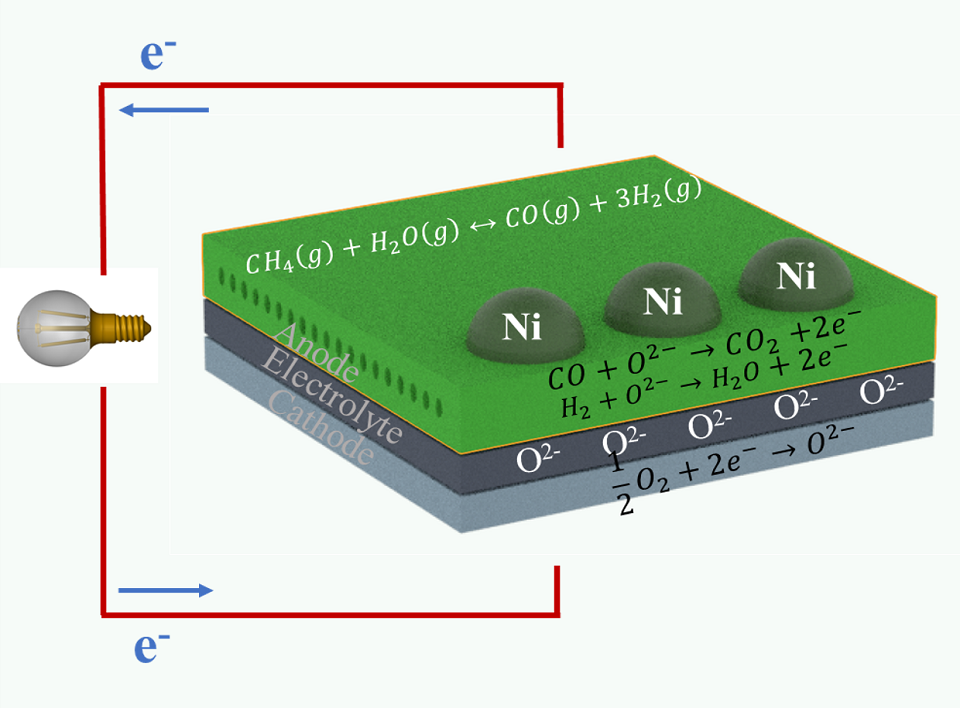

本文研究了掺氢天然气直接内重整平管型固体氧化物电池短堆的长期稳定性和衰减机理。通过约3000小时的实测实验,结果显示,电堆的总体衰减率为2.3% kh-1,电堆中三个金属连接板的面积比电阻分别增加了0.276 Ω·cm2、0.254 Ω·cm2和0.249 Ω·cm2,但电堆中两个电池的电压反而分别增加了3.38 mV·kh-1和3.78 mV·kh-1。电堆衰减主要由金属连接件表层氧化及其与阴极集流层材料反应生成SrCrO4物质,两者共同作用增大了电池与金属连接体间的界面电阻所致。结果表明,以掺氢天然气为燃料直接内重整平管型固体氧化物燃料电池电堆具有良好的稳定性。本文工作为掺氢天然气在固体氧化物燃料电池堆中的直接内重整应用提供了理论参考与实验依据。

汤亚飞 , 武安祺 , 韩贝贝 , 刘华 , 包善军 , 林王林 , 陈铭 , 官万兵 , Subhash C. Singhal . 以掺氢天然气为燃料直接内重整固体氧化物电池堆的稳定性[J]. 电化学, 2024 , 30(1) : 2314001 . DOI: 10.61558/2993-074X.3430

In this work, the long-term stability and degradation mechanism of a direct internal-reforming solid oxide fuel cell stack (IR-SOFC stack) using hydrogen-blended methane steam reforming were investigated. An overall degradation rate of 2.3%·kh-1 was found after the stack was operated for 3000 hours, indicating a good long-term stability. However, the voltages of the two cells in the stack were increased at the rates of 3.38 mV·kh-1 and 3.78 mV·kh-1, while the area specific resistances of the three metal interconnects in the stack were increased to 0.276 Ω·cm2, 0.254 Ω·cm2 and 0.249 Ω·cm2. The degradation of the stack might be caused by segregation of chromium on the surface of metal interconnects and the formation of SrCrO4 insulating phase in the current collecting layer of the cathode, which result in an increase in the interfacial resistance and a decrease in the stack performance. The long-term performance of a flat-tube IR-SOFC stack could be further improved by suitably coating the metal interconnect surface. This work provides theoretical and experimental guideline for the application of hydrogen-blended methane steam reforming in flat-tube IR-SOFC stacks.

/

| 〈 |

|

〉 |