膜电极电解器电解脱硫废水制备硫酸铵副产氢

收稿日期: 2021-12-21

修回日期: 2022-02-14

网络出版日期: 2022-02-23

Simultaneous Hydrogen and (NH4)2SO4 Productions from Desulfurization Wastewater Electrolysis Using MEA Electrolyser

Received date: 2021-12-21

Revised date: 2022-02-14

Online published: 2022-02-23

韦聚才 , 石霖 , 吴旭 . 膜电极电解器电解脱硫废水制备硫酸铵副产氢[J]. 电化学, 2022 , 28(5) : 2112211 . DOI: 10.13208/j.electrochem.211221

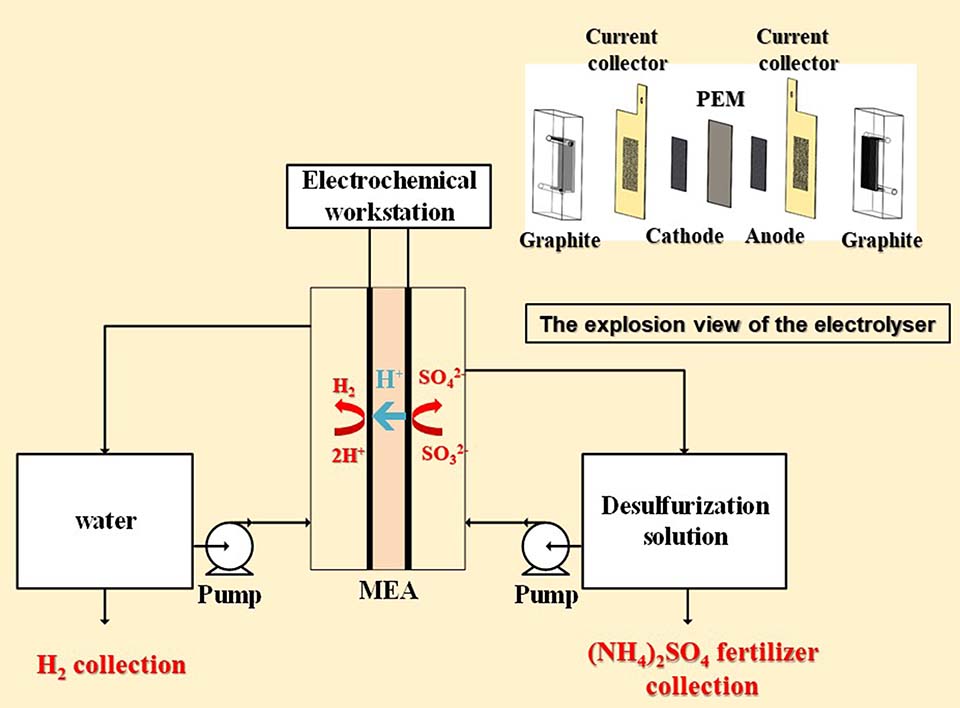

It is preferred to simultaneously recover resource and energy from waster. Sulfur dioxide, SO2, a common air pollutant, a potential energy resource, is a key link to sulfur nature circulation. SO2 can be conversed to NH4HSO3 and (NH4)2SO3 during the ammonia desulfurization process, which can be used to produce (NH4)2SO4 fertilizer. For high quality (NH4)2SO4 fertilizer and high heat transfer efficiency of the evaporative crystallization, HSO3- or SO32- needs to be oxidized to form SO42- before evaporative crystallization. Anodic oxidation of HSO3- or SO32- coupled with hydrogen evolution can significantly reduce cost of hydrogen evolution due to a low reaction potential. This work uses a filter-press membrane electrode assembly electrochemical reactor to recover commercially valuable (NH4)2SO4 fertilizer and produce hydrogen. It can simultaneously achieve waster recycle and energy storage, which is conformed to the domestic circulation and dual carbon goals. The electrooxidation mechanisms and dynamic parameters of (NH4)2SO3 and NH4HSO3 on homemade PtPd2.75/C catalyst were investigated, particularly by cyclic voltammetry and rotating disk electrode system. According to Randles-Sevĉik equation and Levich equation, the number of the electron transfer during the electro-oxidation of SO32- or HSO3- is 1.86. The diffusion coefficients of SO32- and HSO3- are 2.29 × 10-6 cm2·s-1 and 1.18 × 10-5 cm2·s-1, respectively. A 1 cm × 1 cm electrolyser was homemade by graphite. The desulfurization wastewater was used as the anolyte, while water as the catholyte. The anolyte and catholyte were separated by a proton exchange membrane. The homemade PtPd2.75/C catalyst was used as both sulfite oxidation catalyst and hydrogen evolution catalyst. The catalyst was loaded to carbon clothes firstly, and then hot-pressed to the proton exchange membrane to fabricate the membrane electrode assembly. The influences of operation conditions on the electrolyser performances have been studied by potentiodynamic scans and electrochemical impedance spectroscopy. The optimal conditions were chosen as follow: pH = 7.5 of the ammonium sulfite wastewater as the anolyte, pure water as the catholyte, 50 oC. The electrolyser exhibited excellent SO32- electro-oxidation performance and stability. Under the optimal experimental conditions, the electrolyser could achieve 294.63 mA·cm-2 at 1.5 V. At a current density of 200 mA·cm-2, the SO32- conversion rate could reach 94% without exceeding the applied cell voltage of 2 V. It could produce 0.70 t ammonium sulfate and 2.98 kg hydrogen when 1 m3 ammonium sulfite wastewater was electrolyzed for 20 h. The electricity consumption was 137.24 kWh per m3 wastewater, which can create a profit of 1302.70 yuans. Such a strategy has shed a light on further development towards industrial application.

| [1] | Yan Z K(燕中凯), Liu Y(刘媛), Yue T(岳涛), Yan J(闫骏), Han B J(韩斌杰). Selection of flue gas desulfurization process and prospects of desulfurization technology development[J]. Environ. Eng.(环境工程), 2013, 31(6): 58-61+66. |

| [2] | Lu B Y(鲁博颖). Discussion on application of flue gas ammonia desulfurization technology[J]. Chem. Fert. Des.(化肥设计), 2021, 59(3): 39-42. |

| [3] | Gao F(高峰), Qi H M(齐慧敏), Fang X C(方向晨). Research process of the technology of ammonia desulfurization and ammonia decarbonization of flue gas[J]. Contemp. Chem. Ind.(当代化工), 2021, 50(5): 1241-1244. |

| [4] | Xiao W D(肖文德). The development history and prospects of ultra-low emission advanced ammonia desulfurization technology[J]. Chin. Environ. Prot. Ind.(中国环保产业), 2021, (5): 8-9. |

| [5] | Dai M(代蒙), Huang B F(黄帮福), Li L(李露), Wang D F(汪德富), Yang Z Y(杨征宇), Luo F(罗枫), Ye F Y(冶富银), Li M(李明). Main influencing factors of ammonium sulfate crystallization in ammonium desulfurization process[J]. Bull. Chin. Silic. Soc.(硅酸盐通报), 2021, 40(2): 505-512. |

| [6] | Luan H(栾辉), Tang Z H(唐智和), Zhai X J(翟小娟), He W(何为). Problems ammonia process of desulfurization and its countermeasures[J]. Environ. Prot. Oil Gas Fields(油气田环境保护), 2016, 26(6): 29-31+55. |

| [7] | O′Brien J A, Hinkley J T, Donne S W, Lindquist S E. The electrochemical oxidation of aqueous sulfur dioxide: A critical review of work with respect to the hybrid sulfur cycle[J]. Electrochim. Acta, 2010, 55(3): 573-591. |

| [8] | Wei J C, Gu Y Y, Wu X. A desulfurization fuel cell with alkali and sulfuric acid byproducts: A prototype and a model[J]. Sustain. Energ. Fuels, 2021, 5(14): 3666-3675. |

| [9] | Han J, Cheng H Y, Zhang L W, Fu H B, Chen J M. Trash to treasure: Use flue gas SO2 to produce H2 via a photoelectrochemical process[J]. Chem. Eng. J., 2018, 335: 231-235. |

| [10] | U.S. Savannah River National Laboratory. Hybid sulfur process refernce design and cost analysis, SRNL-L1200-2008-00002[R]. 2009. |

| [11] | Chen S, Zhou W, Ding Y N, Zhao G B, Gao J H. Energy-saving cathodic hydrogen production enabled by anodic oxidation of aqueous sodium sulfite solutions[J]. Energy Fuels, 2020, 34(7): 9058-9063. |

| [12] | Márquez-Montes R A, Orozco-Mena R E, Camacho-Dá-vila A A, Pérez-Vega S, Collins-Martínez V H, Ramos-Sánchez V H. Optimization of the electrooxidation of aqueous ammonium sulfite for hydrogen production at near-neutral pH using response surface methodology[J]. Int. J. Hydrog. Energy, 2020, 45(27): 13821-13831. |

| [13] | Wei J C, Gu Y Y, Wu X. A sulfite/air fuel cell with alkali and sulfuric acid byproducts: Bifunctional electrocatalyst for sulfite oxidation and ORR activity[J]. J. Electrochem. Soc., 2021, 168(6): 064520. |

| [14] | Zelinsky A G. Features of sulfite oxidation on gold anode[J]. Electrochim. Acta, 2016, 188: 727-733. |

| [15] | Zelinsky A G, Pirogov B Y. Electrochemical oxidation of sulfite and sulfur dioxide at a renewable graphite electrode[J]. Electrochim. Acta, 2017, 231: 371-378. |

| [16] | Marquez-Montes R A, Orozco-Mena R E, Lardizabal-Gu-tierrez D, Chavez-Flores D, Lopez-Ortiz A, Ramos-San-chez V H. Sulfur dioxide exploitation by electrochemical oxidation of sulfite in near-neutral pH electrolytes: A kinetics and mechanistic study[J]. Electrochem. Commun., 2019, 104: 106481. |

| [17] | Bard A J, Faulkner L R. Electrochemical methods: Fundamentals and applications[M]. New York: John Wiley & Sons, Inc., 2000. |

| [18] | Newman J, Thomas-Alyea K E. Electrochemical systems[M]. Hoboken: John Wiley & Sons, Inc., 2004. |

| [19] | Skaväs E, Hemmingsen T. Kinetics and mechanism of sulphite oxidation on a rotating platinum disc electrode in an alkaline solution[J]. Electrochim. Acta, 2007, 52(11): 3510-3517. |

| [20] | Enache A F, Dan M L, Vaszilcsin N. Electrochemical oxidation of sulphite in neutral media on platinum anode[J]. Int. J. Electrochem. Sci., 2018, 13(5): 4466-4478. |

| [21] | Pletcher D, Walsh F C. Industrial electrochemistry[M]. Netherlands: Springer, 1993. |

| [22] | Cheon S, Kim K, Yoon H C, Han J I. Performance of sulfite/feiiiedta fuel cell: Power from waste in flue gas desulfurization process[J]. Chem. Eng. J., 2019, 375: 122008. |

| [23] | Liu S W(刘少武), Qi Y(齐焉), Liu D(刘东), Liu Y P(刘翼鹏). Sulfuric acid work manual[M]. Nanjing: Southeast University Press(东南大学出版社), 2001. |

| [24] | Steimke J L, Steeper T J, Cólon-Mercado H R, Gorensek M B. Development and testing of a pem SO2-depolarized electrolyzer and an operating method that prevents sulfur accumulation[J]. Int. J. Hydrogen Energy, 2015, 40(39): 13281-13294. |

| [25] | Staser J A, Weidner J W. Sulfur dioxide crossover during the production of hydrogen and sulfuric acid in a PEM electrolyzer[J]. J. Electrochem. Soc., 2009, 156(7): B836-B841. |

| [26] | Santasalo-Aarnio A, Virtanen J, Gasik M. SO2 carry-over and sulphur formation in a SO2-depolarized electrolyser[J]. J. Solid State Electrochem., 2016, 20(6): 1655-1663. |

| [27] | Staser J A. Electrochemical generation of hydrogen via the hybrid sulfur process[D]. University of South Carolina: Dissertations & Theses-Gradworks, 2009. |

| [28] | U.S. Savannah River National Laboratory. Method to prevent sulfur accumulation inside membrane electrode assembly, SRNS-STI-2009-00134[R]. 2009. |

/

| 〈 |

|

〉 |