钛基氧化铱电极电沉积制备技术研究进展

收稿日期: 2020-08-14

修回日期: 2020-08-27

网络出版日期: 2020-09-17

Research Progress in Electrodeposition Technology of Titanium-Based Iridium Oxide Electrode

Received date: 2020-08-14

Revised date: 2020-08-27

Online published: 2020-09-17

吴丹丹 , 吴旭 . 钛基氧化铱电极电沉积制备技术研究进展[J]. 电化学, 2021 , 27(1) : 35 -44 . DOI: 10.13208/j.electrochem.200802

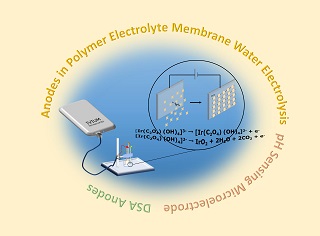

Titanium-based iridium oxide electrode has been widely used in various fields, such as electrocatalytic oxidation, biomedical applications, hydrometallurgical metal recovery, electro-osmotic dewatering, etc. At present, it is mainly prepared by traditional thermal decomposition method, however, which has high cost, cumbersome process, mainly relying on manual labor and cannot be mass-produced yet. It is, therefore, urgently necessary to explore new preparation technologies by focusing on electrodeposition technology, with technological characteristics such as eco-friendly and sustainable development. This article systematically discusses the research progress in iridium oxide electrodeposition preparation technology from the aspects of deposition solution formulation, base material selection and treatment, electrodeposition method and deposition time, etc. Some works and achievements, made by the author's research group, such as a new electrodeposition recipe of titanium-based iridium oxide electrode and the pretreatment of titanium with anodic oxidation for improving the stability of electrodeposited IrO2 electrode are also presented. The current challenges faced by the electrodeposition preparation technology of titanium-based iridium oxide electrode, including bad coating quality, weak bonding ability between coating and substrate, lack of the study on the theory about dynamic of electrodeposition and the problem of industrial applications are analyzed. Based upon the aforementioned challenges, some suggestions, for example, utilizing optimization of the electrodeposition, multi-deposition process combination, metal (such as tantalum, lanthanum) co-deposition, are given to solve for the problem of coating quality. The process of electrodeposition by utilizing in-situ electrochemical methods, and combined with COMSOL and other software to simulate the process, and then starting from both electrochemical theory and crystal growth theory, as well as the gradually perfect the theoretical research on electrodeposition of iridium oxide on titanium are summarized. Finally, the application prospects and future development directions are highlighted. It is expected that this brief review would offer critical insights and useful guidelines for developing superior electrodeposition technology of titanium-based iridium oxide electrode.

Key words: IrO2/Ti electrodes; electrodeposition; industrial applications

/

| 〈 |

|

〉 |