铂基氧还原催化剂在活性和稳定性方面的挑战

收稿日期: 2018-12-05

修回日期: 2019-01-21

网络出版日期: 2020-02-28

基金资助

国家重点研发计划项目(2017YFB0102900);国家自然科学基金(21633008);国家自然科学基金(21875243);国家自然科学基金(21433003);中国科学院战略重点研究先导项目(XDA09030104);俄罗斯基础研究基金会(18-53-53025);俄罗斯基础研究基金会(Fateev Vladimir);吉林省科技发展项目(20170520150JH);吉林省科技发展项目(20170203003SF);吉林省科技发展项目(20180101030JC)

版权

Challenges in the Activity and Stability of Pt-Based Catalysts toward ORR

Received date: 2018-12-05

Revised date: 2019-01-21

Online published: 2020-02-28

Copyright

赵拓 , 罗二桂 , 王显 , 葛君杰 , 刘长鹏 , 邢巍 . 铂基氧还原催化剂在活性和稳定性方面的挑战[J]. 电化学, 2020 , 26(1) : 84 -95 . DOI: 10.13208/j.electrochem.181205

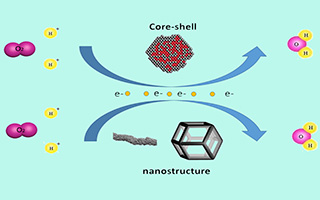

The development of highly efficient oxygen reduction reaction (ORR) catalysts is the key to the commercialization of fuel cells, where the sluggish ORR reaction rate needs to be overcome by adjusting the intermediates adsorption energies on the catalytic surfaces. To-date, platinum (Pt)-based materials are the-state-of-the-art catalysts in terms of both activity and stability in ORR, making them the preferred choice for commercial applications. However, the high cost of Pt-based catalysts limits their widespread use, leading to massive effects paid in reducing Pt loading, improving catalyst activity and stability. This article illustrates the challenges in the ORR reaction and introduces the recent research progresses in Pt-based oxygen reduction catalysts including the ORR mechanism, core-shell structures, one-dimensional nanostructure, and other representative works of Pt-based catalysts. Some perspectives in the future development trend of Pt-based catalysts are given at the end of the paper, hoping to provide readers with some ideological inspiration.

/

| 〈 |

|

〉 |