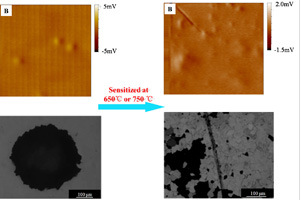

敏化处理304不锈钢局部腐蚀行为的扫描微电极法研究

收稿日期: 2013-01-31

修回日期: 2013-03-28

网络出版日期: 2013-04-05

基金资助

国家自然科学基金项目(No. 21021002)资助

Localized Corrosion Behavior of Sensitized 304 Stainless Steel by Scanning Reference Electrode Technique

Received date: 2013-01-31

Revised date: 2013-03-28

Online published: 2013-04-05

叶陈清 , 胡融刚 , 侯瑞青 , 王小平 , 杜荣归 , 林昌健 . 敏化处理304不锈钢局部腐蚀行为的扫描微电极法研究[J]. 电化学, 2013 , 19(6) : 507 -511 . DOI: 10.13208/j.electrochem.130217

/

| 〈 |

|

〉 |