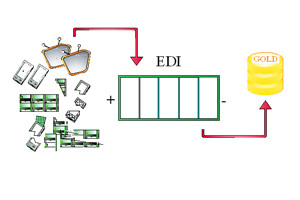

连续电提取浓缩技术

收稿日期: 2012-12-25

修回日期: 2013-03-15

网络出版日期: 2013-03-15

基金资助

国家自然科学基金项目(No.21073161,No.21173188)资助

Continuous Electroextraction and Concentration Technology

Received date: 2012-12-25

Revised date: 2013-03-15

Online published: 2013-03-15

任琼 , 廖文 , 吴祖成 . 连续电提取浓缩技术[J]. 电化学, 2013 , 19(5) : 454 -459 . DOI: 10.61558/2993-074X.2136

/

| 〈 |

|

〉 |