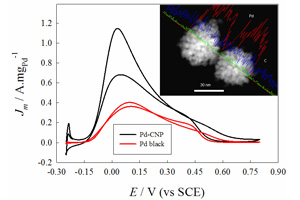

碳纳米粒子支撑的钯纳米催化剂在甲酸氧化中的电催化活性

收稿日期: 2012-01-20

修回日期: 2012-02-01

网络出版日期: 2012-12-28

基金资助

This work was supported, in part, by the National Science Foundation (CHE–1012256 and DMR–0804049) and by the ACS-Petroleum Research Fund (49137–ND10). J. H. was supported, in part, by a research fellowship from the China Scholarship Council. TEM work was performed as a User Project at the National Center for Electron Microscopy, Lawrence Berkeley National Laboratory, which is supported by the US Department of Energy

Electrocatalytic Activity of Palladium Nanocatalysts Supported on Carbon Nanoparticles in Formic Acid Oxidation

Received date: 2012-01-20

Revised date: 2012-02-01

Online published: 2012-12-28

Supported by

This work was supported, in part, by the National Science Foundation (CHE–1012256 and DMR–0804049) and by the ACS-Petroleum Research Fund (49137–ND10). J. H. was supported, in part, by a research fellowship from the China Scholarship Council. TEM work was performed as a User Project at the National Center for Electron Microscopy, Lawrence Berkeley National Laboratory, which is supported by the US Department of Energy

黄洁 , 周志有 , 宋洋 , 康雄武 , 刘珂 , 周万城 , 陈少伟 . 碳纳米粒子支撑的钯纳米催化剂在甲酸氧化中的电催化活性[J]. 电化学, 2012 , 18(6) : 508 -514 . DOI: 10.61558/2993-074X.2619

/

| 〈 |

|

〉 |