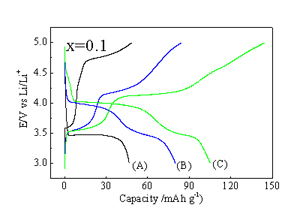

详细研究了橄榄石结构磷酸盐脱嵌锂过程的控制步骤,发现就多元橄榄石结构Li(FeMnCo)PO4磷酸盐而言,在碳含量比较低时在充放电曲线之间存在非对称现象.充电时与Fe2+/Fe3+电对对应的容量小于理论容量,与Co2+/Co3+电对对应的容量大于理论容量;放电时与Co2+/Co3+电对对应容量远小于相应的充电容量,但是与Fe2+/Fe3+电对对应的放电容量远大于与该电对对应的充电容量.电极呈现出以Co2+/Co3+电对充电,以Fe2+/Fe3+电对放电的行为.作者认为在充电和放电过程中活性材料颗粒内部存在内界面,充电时内界面内部组成是Fe2+、Co2+、Mn2+和低浓度的Fe3+,而内界面外部组成是Co3+、Mn2+、Fe3+和低浓度的Co2+.非对称现象的主要原因是内界面移动速度缓慢,碳含量低时慢的内界面移动速度是电化学脱嵌锂过程的主要控制步骤.

吴军

,

李志虎

,

吴群

,

李德成

,

郑军伟

,

徐艳辉

. 橄榄石结构磷酸盐脱/嵌锂过程的控制步骤研究[J]. 电化学, 2012

, 18(2)

: 157

-161

.

DOI: 10.61558/2993-074X.2897

In the present work the rate-limited step during Li intercalation/deintercalation processes for olivine-type phosphate has been discussed. It is found that the increase in the carbon content is effective to improve the electrode capacity and the electrochemical activity of the Mn element in the active materials. It is also found that the asymmetric phenomenon exists in the charge-discharging curves, especially when the carbon content is low. During charging the Fe2+/Fe3+ the plateau capacity is much less than the corresponding theoretical capacity, while the capacity that corresponds to Co2+/Co3+ couple is more than the theoretical capacity. The discharge capacity of Co2+/Co3+ couple is far less than the charged capacity, while the discharge capacity of Fe2+/Fe3+ couple is far larger than the corresponding charged capacity. The electrode is being charged with Co2+/Co3+, but discharged with Fe2+/Fe3+ couple. The internal interface is assumed to be presented during the charging and discharging. Accordingly, the compositions inside the internal interface are Fe2+, Co2+, Mn2 and Fe3+ of low concentration during the charging, while those outside the internal interface are Co3+, Mn2+, Fe3+ and Co2+ of low concentration. It should be concluded that the asymmetric phenomenon is attributed to the slow moving rate of the internal interface. The movement of the internal interface is proposed to be the rate-limited step of electrochemical lithium intercalation/deintercalation reaction.