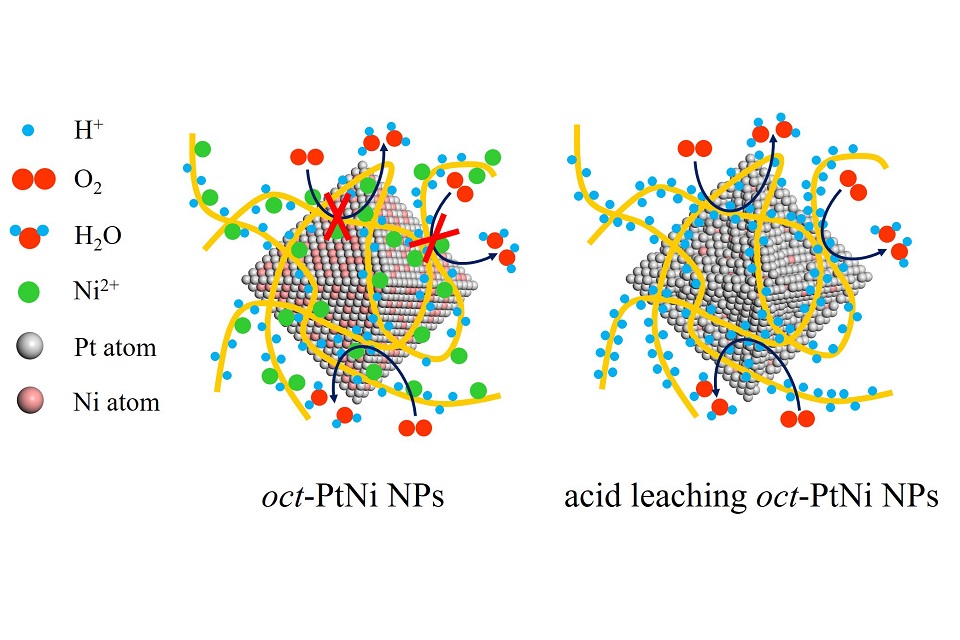

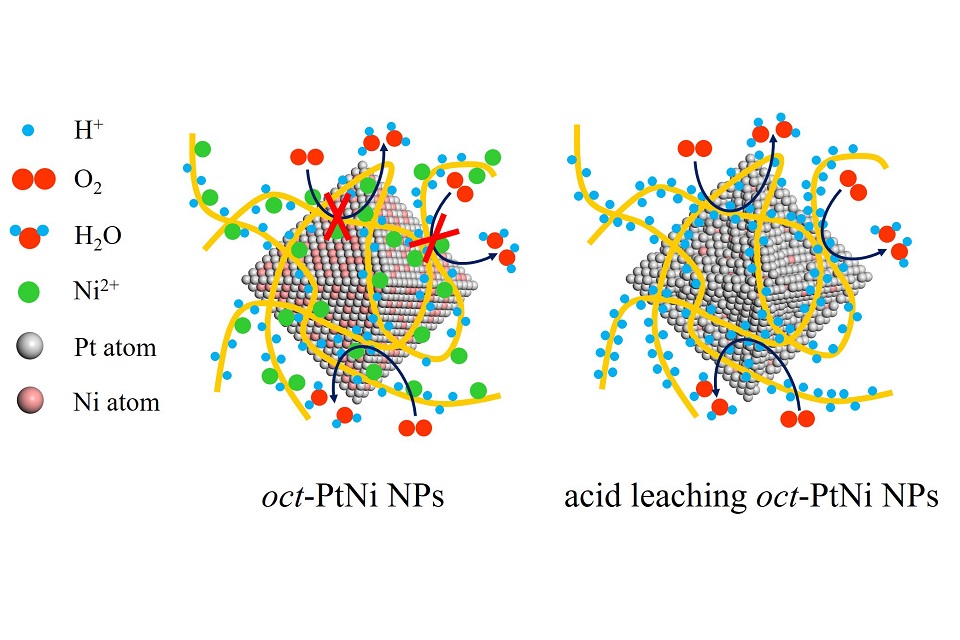

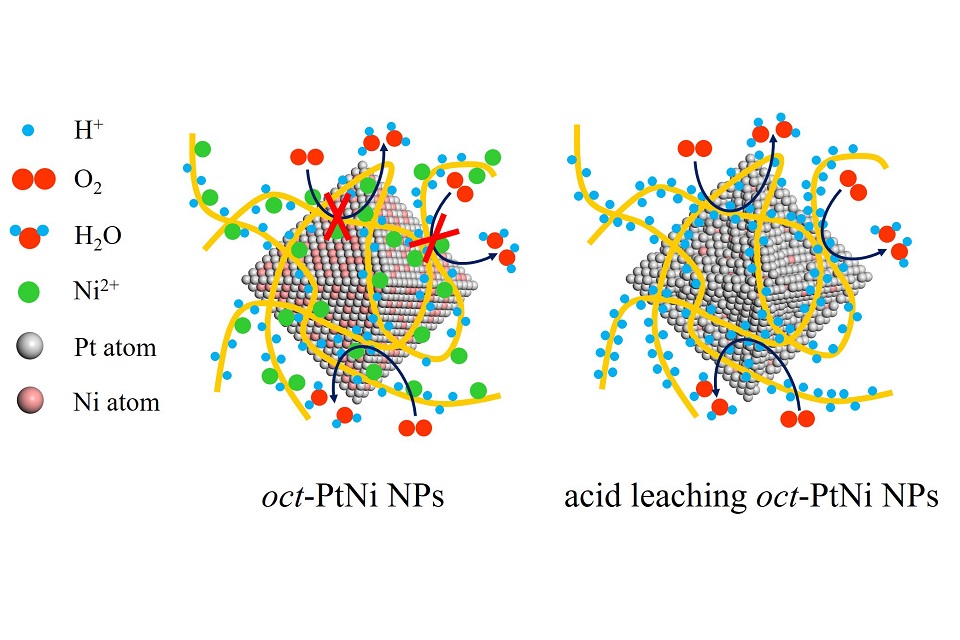

质子交换膜燃料电池(PEMFC)是一种有前景的能量转换装置,但其大规模商业应用受制于高昂的成本和较低的性能。PEMFC的性能主要受限于阴极氧还原反应(ORR)的动力学。铂是对氧还原反应催化活性最高的单金属,但是其性能仍难以满足商业化应用。前期研究表明,铂镍八面体纳米粒子(oct-PtNi-NPs)在半电池中具有优异的ORR活性,但其在膜电极组件(MEA)中的性能报道较少。本论文研究了碳载铂镍八面体纳米粒子(oct-PtNi/C)作为阴极催化剂的膜电极性能。研究结果表明,温和的酸洗条件可溶解oct-PtNi/C表面不稳定的Ni原子,得到PNC-A催化剂;以PNC-A催化剂为阴极催化剂的MEA性能提高:阴极Pt负载量为0.2 mg∙cm-2时,MEA的最大功率密度达到1.0 W∙cm-2,比使用Pt/C作为催化剂时高15%;30,000圈加速老化实验(ADT)后,使用PNC-A催化剂的MEA的性能保持率为82%,高于Pt/C(74%)。本论文研究了使用PNC-A催化剂作为PEMFC阴极催化剂的可能性,提高了PEMFC的性能,同时降低了贵金属Pt的用量。

丰紫薇, 陈海忠, 段骁, 唐玲, 赵云昆, 黄龙

. 碳载铂镍八面体纳米粒子(oct-PtNi/C)作为质子交换膜燃料电池阴极催化剂的性能研究[J]. 电化学, 0

: 0

.

DOI: 10.61558/2993-074X.3588

Proton exchange membrane fuel cells (PEMFCs) is considered as a promising renewable power source. However, the massive commercial application of PEMFCs was greatly hindered by their high expense and less-satisfied performance mainly due to the sluggish oxygen reduction reaction (ORR) kinetics even on state-of-the-art Pt catalyst. Octahedral PtNi nanoparticles (oct-PtNi NPs) with excellent ORR activity in half-cell have been widely studied, while their performance in membrane electrode assembly (MEA) was much less reported. Herein, we investigated the MEA performance using carbon supported oct-PtNi NPs (oct-PtNi/C) as cathode catalyst. Under mild acid washing condition, the surface Ni atoms of oct-PtNi/C were largely removed, and the performance of the MEA using the acid-leaching oct-PtNi/C (PNC-A) as the cathode catalyst was greatly improved. The maximum power density of the MEA reaches 1.0 W·cm-2 with cathode Pt loading of 0.2 mg·cm-2, which is 15% higher than that using Pt/C as the catalyst. After 30k accelerated degradation test (ADT), the MEA using PNC-A as catalysts shows a performance retention of 82%, higher than that of Pt/C (74%). The results reported here verify the possibility of using PNC-A as an advanced cathode catalyst in PEMFCs, thus can enhancing the performance of PEMFCs while lowering the amount of expensive Pt.