人工智能在锂离子电池研发中的应用

收稿日期: 2022-08-31

修回日期: 2022-09-23

网络出版日期: 2022-11-14

Application of Artificial Intelligence to Lithium-Ion Battery Research and Development

Received date: 2022-08-31

Revised date: 2022-09-23

Online published: 2022-11-14

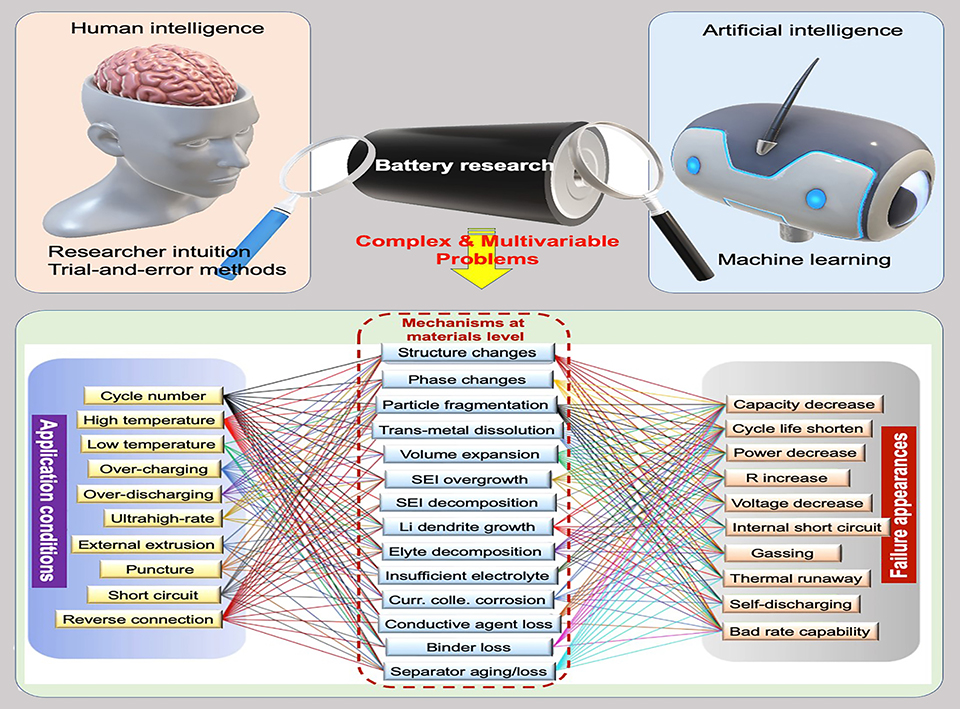

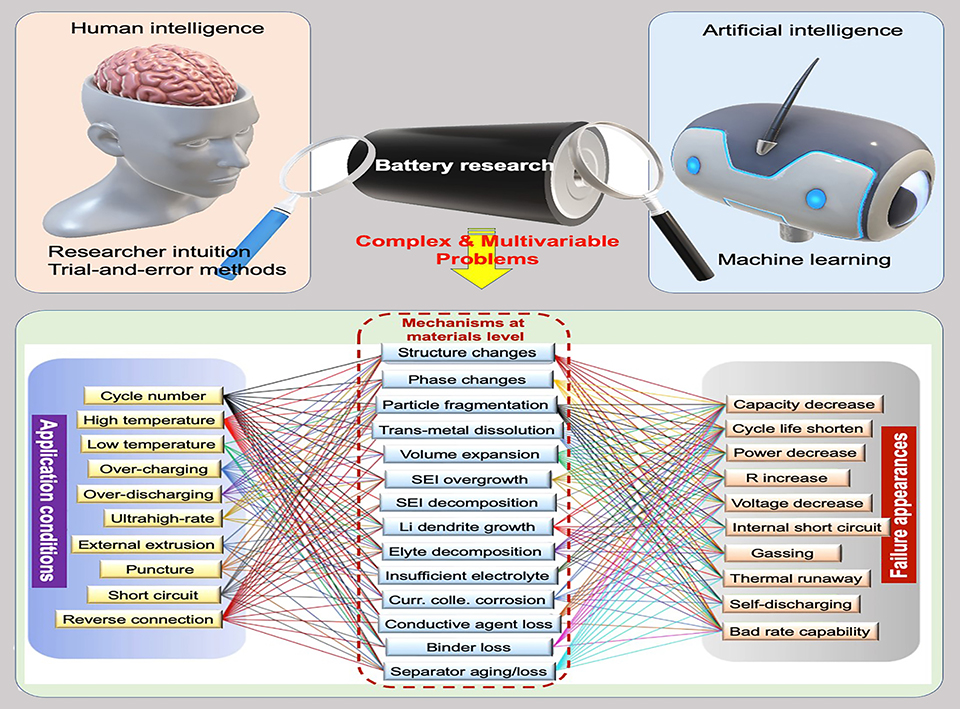

锂离子电池已成为解决现代社会储能问题的最佳解决方案之一。然而,电池材料和器件开发都是复杂的多变量问题,传统的依赖研究人员进行实验的试错法在电池性能提升方面遇到了瓶颈。人工智能(AI)具有强大的高速、海量数据处理能力,是上述突破研究瓶颈的最具潜力的技术。其中,机器学习 (ML) 算法在评估多维数据变量和集合之间的组合关联方面的独特优势有望帮助研究人员发现不同因素之间的相互作用规律并阐明材料合成和设备制造的机制。本综述总结了锂离子电池传统研究方法遇到的各种挑战,并详细介绍了人工智能在电池材料研究、电池器件设计与制造、材料与器件表征、电池循环寿命与安全性评估等方面的应用。最重要的是,我们介绍了AI和ML在电池研究中面临的挑战,并讨论了它们应用的缺点和前景。我们相信,未来实验科学家、数学建模专家和AI专家之间更紧密的合作将极大地促进AI和ML方法用以解决传统方法难以克服的电池和材料问题。

朱振威 , 邱景义 , 王莉 , 曹高萍 , 何向明 , 王京 , 张浩 . 人工智能在锂离子电池研发中的应用[J]. 电化学, 2022 , 28(12) : 2219003 . DOI: 10.13208/j.electrochem.2219003

Lithium-ion batteries (LIBs) have become one of the best solutions to the energy storage issue in modern society. However, the battery materials and device development are both complex, and involve multivariable problems. Traditional trial-and-error approach, which relies on researchers to conduct experiments, has encountered bottlenecks in the improvement of the battery performance. Artificial intelligence (AI) is the most potential technology to deal with this issue due to its powerful high-speed and capabilities of processing massive data. In particular, the capability of machine learning (ML) algorithms in assessing multidimensional data variables and discovering patterns in the sets are expected to assist researchers in discovering patterns and elucidating the mechanisms of material synthesis and device fabrication. This review summarizes various challenges encountered in traditional research methods of LIBs and introduces the applications of AI in battery material research, battery device design and manufacturing, material and device characterizations, and battery cycle life and safety assessment in detail. Most importantly, we present the challenges faced by AI and ML in battery research, and discuss the shortcomings and prospects of their applications. We believe that a closer collaboration among experimentalists, modeling specialists, and AI experts in the future will greatly facilitate AI and ML methods for solving battery and materials problems that are difficult to be solved by traditional methods.

/

| 〈 |

|

〉 |