蚀刻引线框架用的弱碱性无氰镀银工艺的研究

收稿日期: 2022-03-08

修回日期: 2022-04-10

网络出版日期: 2022-05-18

基金资助

嘉兴市科技计划项目(编号2019AD32017)

Study on Weak Alkaline Cyanide-Free Silver Plating Process for Etching Lead Frame

Received date: 2022-03-08

Revised date: 2022-04-10

Online published: 2022-05-18

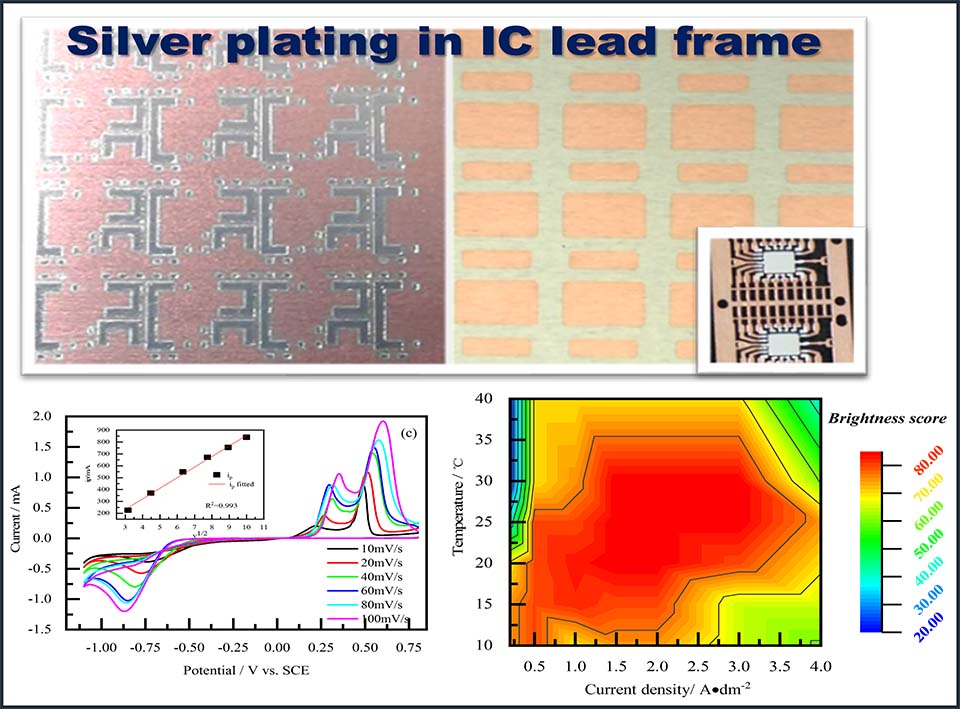

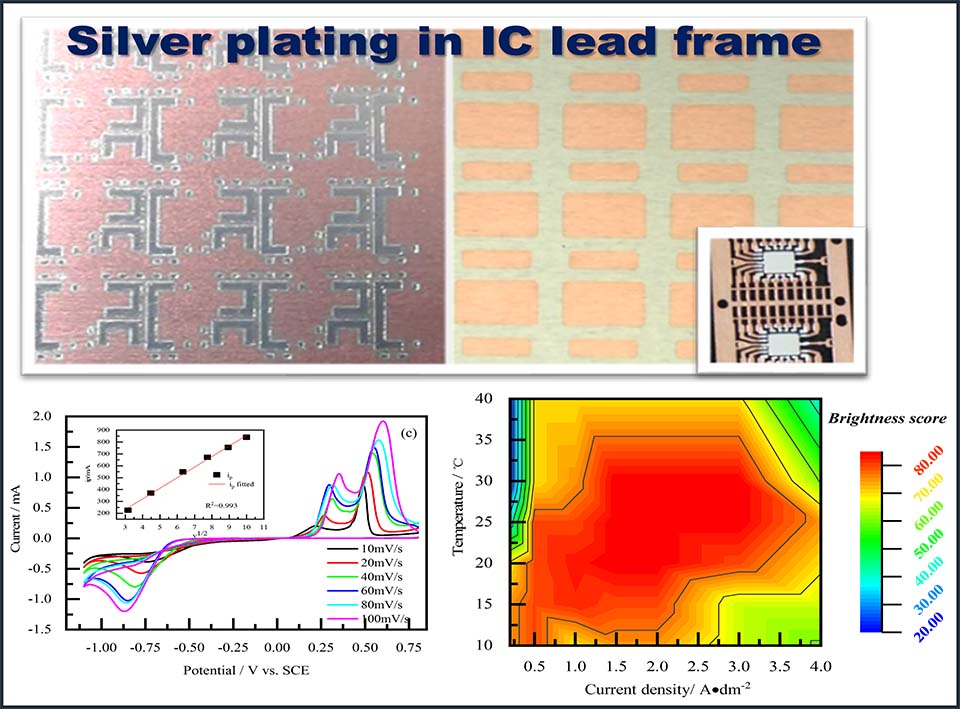

蚀刻引线框架作为集成电路芯片载体的新发展方向,近年来在微电子行业逐步得到应用。由于蚀刻引线框架在制备中需要用到多层具有特定图形的非耐碱的光刻胶膜,而传统的氰化镀银无法满足这一工艺需求,因此发展弱碱性的无氰镀银工艺具有极大应用价值。本文研究了基于5,5-二甲基乙内酰脲(DMH)无氰镀银体系的弱碱性镀银工艺,利用循环伏安法和计时电流法考察了该体系的电沉积行为与银结晶的成核机理;通过改变系列工艺条件确定的该工艺的有效工作窗口;并在优化的工艺条件下表征了镀层性能与镀液性能。结果表明该镀银层结晶细腻,平均颗粒尺度在16.7±3.6 nm。XRD测试表明其等效的晶粒尺度在43.6±3.0 nm,且(200)晶面为择优取向晶面。该镀银层白度为7.2%,光亮度为117 Gs,硬度为74±4 Hv。镀液性能测试表明,该镀液电流效率达到了99.2%(30 oC/0.6 ASD), 30 oC条件下的分散能力约为83%。上述测试及实际蚀刻引线框架样品的试镀均展示了该工艺在实际应用中的潜在价值。

赵健伟 , 朱海锋 , 于晓辉 , 袁桂云 , 孙志 . 蚀刻引线框架用的弱碱性无氰镀银工艺的研究[J]. 电化学, 2022 , 28(6) : 2104551 . DOI: 10.13208/j.electrochem.210455

As a new development direction of integrated circuit chip carrier, etched lead frame has been gradually applied in microelectronics industry in recent years. Since the preparation of the etched lead frame requires the use of multiple layers of non-alkali-resistant photoresist films with specific patterns, and the traditional cyanide silver plating is unable to meet this requirement, making that the development of weakly alkaline cyanide free silver plating process has great significance. In this paper, a weak alkaline silver plating process based on 5,5-dimethylhydantoin (DMH) cyanide-free silver plating system was studied. The electrodeposition behavior of the system and the nucleation mechanism of silver crystallization were investigated by cyclic voltammetry (CV) and chronoamperometry (CA); By changing a series of conditions, the effective working range of the process was determined, and the properties of the coating and the bath were characterized under the optimized process conditions. The results showed that the crystals of the silver plating layer were fine, and the average particle size was 16.7 ± 3.6 nm. From the XRD test results, the effective grain size was 43.6 ± 3 nm, and the (200) crystal surface was the preferred orientation crystal plane. Coating performance tests included whiteness, brightness and hardness, which were 7.2%, 117 Gs and 74 ± 4 Hv, respectively. In addition, the performance test of the bath showed that the current efficiency of the bath reached 99.2% with the temperature was 30 oC and the current density was 0.6 ASD, and the throwing power was about 83% at 30 oC. The results of the above tests and the actual etched lead frame samples have demonstrated that this process is of great value in practical application.

Keywords: cyanide-free silver plating; lead frame; nucleation mechanism; bath properties; coating properties

/

| 〈 |

|

〉 |