定量的复合金属锂作为三维泡沫锂电极用于锂电池的研究

Quantitative Lithium Composite as 3D Lithium Foam Anode for Lithium Metal Battery

Received date: 2022-02-07

Revised date: 2022-03-02

Online published: 2022-03-18

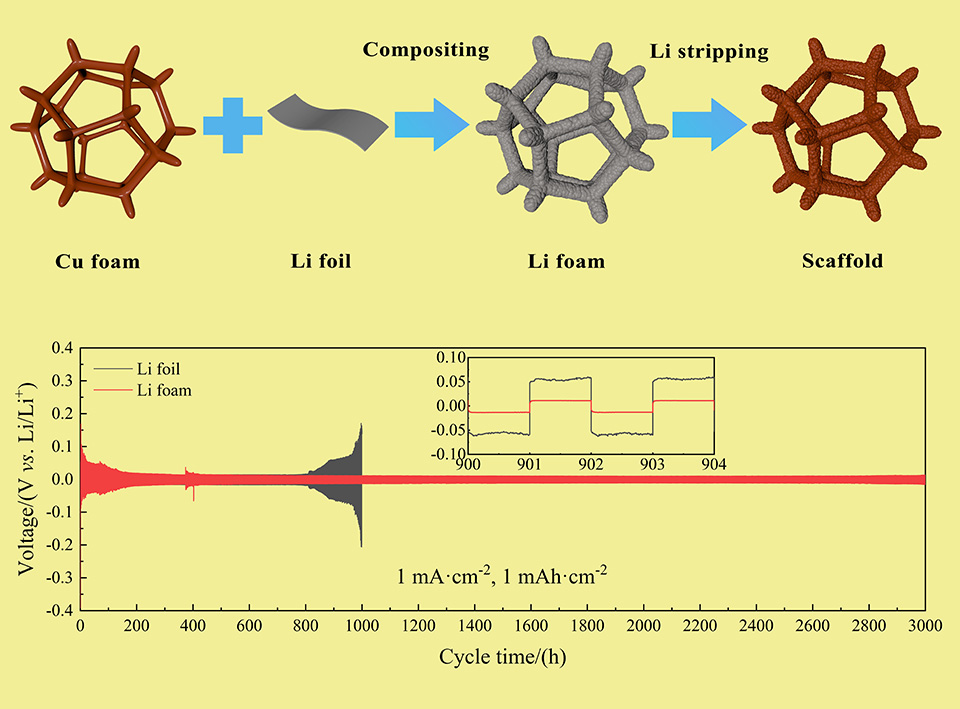

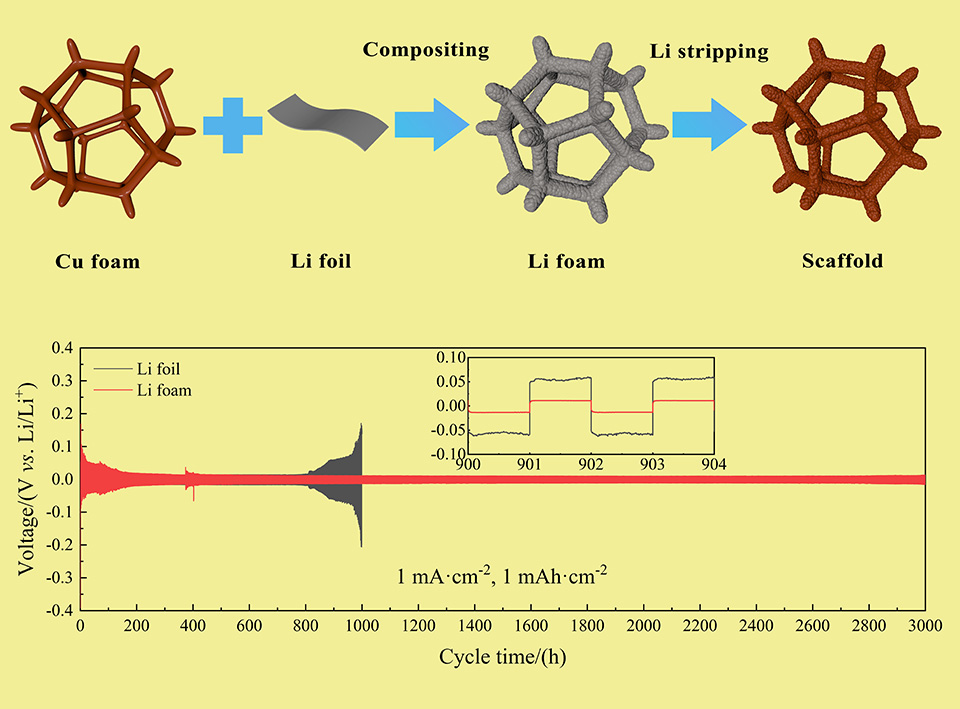

金属锂作为电池的负极材料具有极高的比容量和极低的氧化还原电位,能够显著提升电池的能量密度。然而,金属锂负极在实际应用中所面临的主要问题是锂枝晶、界面副反应和电极体积变化大的难题。在本文中,我们提出了一种通过将定量的金属锂与三维骨架进行复合形成三维泡沫锂负极的策略,并利用三维泡沫锂来抑制锂枝晶的生长和缓解电极的体积变化。因此,三维泡沫锂电极有利于金属锂负极的高效利用,并能借助其与平面锂箔相比更高的比表面积和更多的反应位点来提升电池的倍率性能。因此,通过采用三维泡沫锂,对称电池的循环寿命和倍率性能都得到了有效的提升。EIS数据结果表明,三维泡沫锂能够减小对称电池的电荷转移阻抗。而且,将三维泡沫锂作为负极组装的LTO全电池,与锂箔作为负极相比,循环1000周平均放电比容量从65 mAh·g-1提升至121 mAh·g-1。

李虎东 , 贾维尚 , 闫新秀 , 阳耀月 . 定量的复合金属锂作为三维泡沫锂电极用于锂电池的研究[J]. 电化学, 2022 , 28(8) : 2202051 . DOI: 10.13208/j.electrochem.2202051

Lithium (Li) metal as an anode material for batteries has extremely high specific capacity and extremely low redox potential, which can significantly improve the energy density of the battery. However, the main problems faced by the use of Li metal anodes are Li dendrite growth, interfacial side reaction and volumetric change of electrode. Herein, a strategy to prepare the three-dimensional (3D) Li foam by combining 3D scaffold with quantitative Li was proposed to suppress Li dendrites growth and alleviate electrode volumetric change. The 3D Li foam facilitated the efficient utilization of Li metal by suppressing the Li dendrite growth, mitigating the volumetric change, and improving the rate performance. Therefore, the cycling lifetime and rate performance of the symmetric cells using the 3D Li foam were improved. The EIS results showed that the 3D Li foam reduced the charge transfer resistance of the symmetric cells. And the average discharge specific capacity of the LTO cell during 1000 cycles was enhanced from 65 mAh·g-1 to 121 mAh·g-1 by using the 3D Li foam.

| [1] | Scrosati B, Hassoun J, Sun Y K. Lithium-ion batteries. A look into the future[J]. Energy Environ. Sci., 2011, 4(9): 3287-3295. |

| [2] | Chu S, Cui Y, Liu N. The path towards sustainable energy[J]. Nat. Mater., 2017, 16(1): 16-22. |

| [3] | Xu W, Wang J L, Ding F, Chen X L, Nasybulin E, Zhang Y H, Zhang J G. Lithium metal anodes for rechargeable batteries[J]. Energy Environ. Sci., 2014, 7(2): 513-537. |

| [4] | Lin D C, Liu Y Y, Cui Y. Reviving the lithium metal anode for high-energy batteries[J]. Nat. Nanotechnol., 2017, 12(3): 194-206. |

| [5] | Choi J W, Aurbach D. Promise and reality of post-lithium-ion batteries with high energy densities[J]. Nat. Rev. Mater., 2016, 1(4): 16013. |

| [6] | Goodenough J B, Kim Y. Challenges for rechargeable Li batteries[J]. Chem. Mater., 2010, 22(3): 587-603. |

| [7] | Wang D, Liu Y M, Li G W, Qin C C, Huang L, Wu Y P. Liquid metal welding to suppress Li dendrite by equalized heat distribution[J]. Adv. Funct. Mater., 2021, 31(47): 2106740. |

| [8] | Wang D, Qin C C, Li X L, Song G Q, Liu Y M, Cao M Y, Huang L, Wu Y P. Synchronous healing of Li metal anode via asymmetrical bidirectional current[J]. iScience, 2020, 23(1): 100781. |

| [9] | Lin D C, Liu Y Y, Pei A, Cui Y. Nanoscale perspective: materials designs and understandings in lithium metal anodes[J]. Nano Res., 2017, 10(12): 4003-4026. |

| [10] | Kong L, Peng H J, Huang J Q, Zhang Q. Review of nano-structured current collectors in lithium-sulfur batteries[J]. Nano Res., 2017, 10(12): 4027-4054. |

| [11] | Shi S Q, Gao J, Liu Y, Zhao Y, Wu Q, Ju W W, Ouyang C Y, Xiao R J. Multi-scale computation methods: Their applications in lithium-ion battery research and development[J]. Chinese Phys. B, 2016, 25(1): 018212. |

| [12] | Liu F, Xu R, Wu Y C, Boyle D T, Yang A K, Xu J W, Zhu Y Y, Ye Y S, Yu Z A, Zhang Z W, Xiao X, Huang W X, Wang H S, Chen H, Cui Y. Dynamic spatial progression of isolated lithium during battery operations[J]. Nature, 2021, 600(7890): 659-663. |

| [13] | Zhang Z W, Li Y Z, Xu R, Zhou W J, Li Y B, Oyakhire S T, Wu Y C, Xu J W, Wang H S, Yu Z A, Boyle D T, Huang W, Ye Y S, Chen H, Wan J Y, Bao Z N, Chiu W, Cui Y. Capturing the swelling of solid-electrolyte interphase in lithium metal batteries[J]. Science, 2022, 375(6576): 66-70. |

| [14] | Jia W S, Wang Q J, Yang J Y, Fan C, Wang L P, Li J Z. Pretreatment of lithium surface by using iodic acid (HIO3) to improve its anode performance in lithium batteries[J]. ACS Appl. Mater. Inter., 2017, 9(8): 7068-7074. |

| [15] | Luo Z, Qiu X J, Liu C, Li S, Wang C W, Zou G Q, Hou H S, Ji X B. Interfacial challenges towards stable Li metal anode[J]. Nano Energy, 2021, 79: 105507. |

| [16] | Jia W S, Fan C, Wang L P, Wang Q J, Zhao M J, Zhou A J, Li J Z. Extremely accessible potassium nitrate (KNO3) as the highly efficient electrolyte additive in lithium battery[J]. ACS Appl. Mater. Inter., 2016, 8(24): 15399-15405. |

| [17] | Zheng J M, Engelhard M H, Mei D H, Jiao S H, Polzin B J, Zhang J G, Xu W. Electrolyte additive enabled fast charging and stable cycling lithium metal batteries[J]. Nat. Energy, 2017, 2(3): 17012. |

| [18] | Jiao S H, Ren X D, Cao R G, Engelhard M H, Liu Y Z, Hu D H, Mei D H, Zheng J M, Zhao W G, Li Q Y, Liu N, Adams B D, Ma C, Liu J, Zhang J G, Xu W. Stable cycling of high-voltage lithium metal batteries in ether electrolytes[J]. Nat. Energy, 2018, 3(9): 739-746. |

| [19] | Xiang J W, Yuan L X, Shen Y, Cheng Z X, Yuan K, Guo Z Z, Zhang Y, Chen X, Huang Y H. Improved rechargeability of lithium metal anode via controlling lithium-ion flux[J]. Adv. Energy Mater., 2018, 8(36): 1802352. |

| [20] | Zhang R, Cheng X B, Zhao C Z, Peng H J, Shi J L, Huang J Q, Wang J F, Wei F, Zhang Q. Conductive nanostructured scaffolds render low local current density to inhibit lithium dendrite growth[J]. Adv. Mater., 2016, 28(11): 2155-2162. |

| [21] | Zhang R H, Li Y, Qiao L, Li D W, Deng J L, Zhou J J, Xie L, Hou Y, Wang T, Tian W, Cao J C, Cheng F L, Yang B, Liang K, Chen P, Kong B. Atomic layer deposition assisted superassembly of ultrathin ZnO layer decorated hierarchical Cu foam for stable lithium metal anode[J]. Energy Storage Mater., 2021, 37: 123-134. |

| [22] | Ye H, Xin S, Yin Y X, Li J Y, Guo Y G, Wan L J. Stable Li plating/stripping electrochemistry realized by a hybrid Li reservoir in spherical carbon granules with 3D conducting skeletons[J]. J. Am. Chem. Soc., 2017, 139(16): 5916-5922. |

| [23] | Jia W S, Chen T, Wang Y, Qu S J, Yao Z Y, Liu Y C, Yin Y, Zou W, Zhou F, Li J Z. Porous equipotential body with heterogeneous nucleation sites: A novel 3D composite current collector for lithium metal anode[J]. Electrochim. Acta, 2019, 309: 460-468. |

| [24] | Shi P, Zhang X Q, Shen X, Zhang R, Liu H, Zhang Q. A review of composite lithium metal anode for practical applications[J]. Adv. Mater. Technol., 2020, 5(1): 1900806. |

| [25] | Wang H S, Liu Y Y, Li Y Z, Cui Y. Lithium metal anode materials design: Interphase and host[J]. Electrochem. Energy Rev., 2019, 2(4): 509-517. |

| [26] | Hafez A M, Jiao Y C, Shi J J, Ma Y, Cao D X, Liu Y Y, Zhu H L. Stable metal anode enabled by porous lithium foam with superior ion accessibility[J]. Adv. Mater., 2018, 30(30): 1802156. |

| [27] | Huang S B, Chen L, Wang T S, Hu J K, Zhang Q F, Zhang H, Nan C W, Fan L Z. Self-propagating enabling high lithium metal utilization ratio composite anodes for lithium metal batteries[J]. Nano Lett., 2021, 21(1): 791-797. |

| [28] | Yang T Z, Sun Y W, Qian T, Liu J, Liu X J, Rosei F, Yan C L. Lithium dendrite inhibition via 3D porous lithium metal anode accompanied by inherent SEI layer[J]. Energy Storage Mater., 2020, 26: 385-390. |

| [29] | Jia W S, Liu Y C, Wang Z H, Qing F Z, Li J Z, Wang Y, Xiao R J, Zhou A J, Li G B, Yu X Q, Hu Y S, Li H, Wang Z X, Huang X J, Chen L Q. Low-temperature fusion fabrication of Li-Cu alloy anode with in situ formed 3D framework of inert LiCux nanowires for excellent Li storage performance[J]. Sci. Bull., 2020, 65(22): 1907-1915. |

| [30] | Jia W S, Li H D, Wang Z H, Liu Y C, Yang Y Y, Li J Z. 3D composite lithium metal with multilevel micro-nano structure combined with surface modification for stable lithium metal anodes[J]. Appl. Surf. Sci., 2021, 570: 151159. |

| [31] | Adair K R, Iqbal M, Wang C H, Zhao Y, Banis M N, Li R Y, Zhang L, Yang R, Lu S G, Sun X L. Towards high performance Li metal batteries: Nanoscale surface modification of 3D metal hosts for pre-stored Li metal anodes[J]. Nano Energy, 2018, 54: 375-382. |

| [32] | Chazalviel J N. Electrochemical aspects of the generation of ramified metallic electrodeposits[J]. Phys. Rev. A, 1990, 42(12): 7355-7367. |

| [33] | Jin S, Sun Z W, Guo Y L, Qi Z K, Guo C K, Kong X H, Zhu Y W, Ji H X. High areal capacity and lithium utilization in anodes made of covalently connected graphite microtubes[J]. Adv. Mater., 2017, 29(38): 1700783. |

| [34] | Zuo T T, Wu X W, Yang C P, Yin Y X, Ye H, Li N W, Guo Y G. Graphitized carbon fibers as multifunctional 3D current collectors for high areal capacity Li anodes[J]. Adv. Mater., 2017, 29(29): 1700389. |

/

| 〈 |

|

〉 |