不同电位下极化后的纯钛表面生物污损行为

收稿日期: 2021-09-06

修回日期: 2021-10-18

网络出版日期: 2021-10-27

基金资助

国家自然科学基金项目(51901198);国家自然科学基金项目(51731008)

Biofouling Behaviors of Pure Titanium Surface Polarized at Different Potentials

Received date: 2021-09-06

Revised date: 2021-10-18

Online published: 2021-10-27

戴昭霞 , 郑大江 , 宋光铃 , 冯丹青 , 苏培 . 不同电位下极化后的纯钛表面生物污损行为[J]. 电化学, 2022 , 28(5) : 2109061 . DOI: 10.13208/j.electrochem.210906

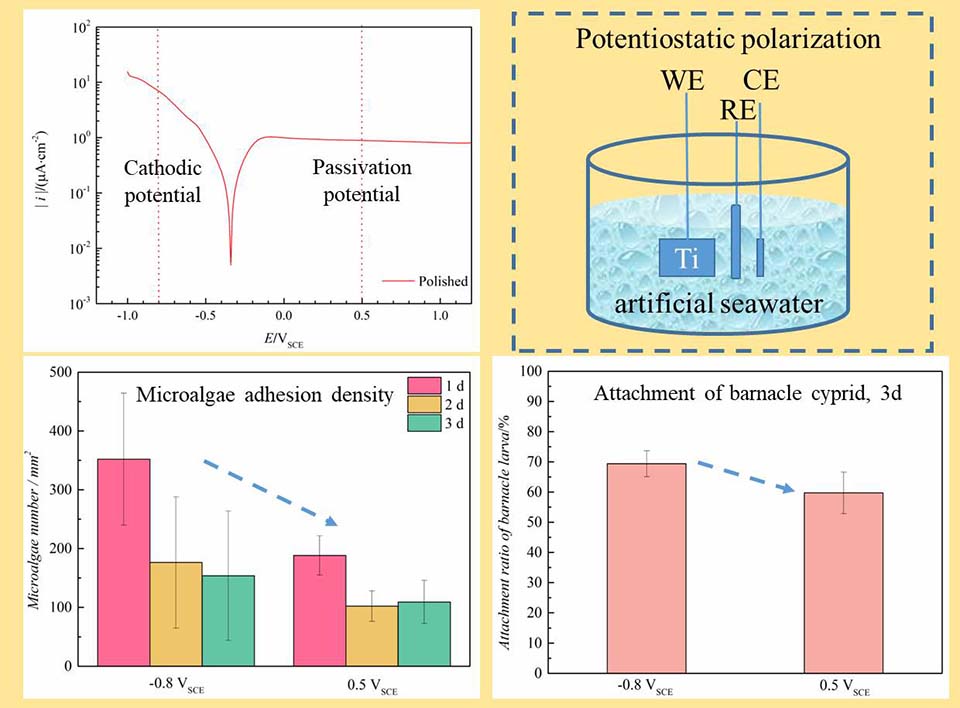

Titanium (Ti) and its alloys are commonly used as engineering materials. Although they have been widely used in marine environments, they are also facing serious threats of biofouling. Therefore, it is necessary to investigate the relationship between electrochemical behavior and bioaffinity of titanium oxide film in seawater to explore effective surface treatment technology to reduce biofouling. In this work, the cathodic potential of -0.8 VSCE and the passivation potential of 0.5 VSCE were directly applied to the TA2 Ti in artificial seawater for potentionstatic polarization treatment to prepare two kinds of surface films with different states and then to monitor the electrochemical behaviors of the samples in different solutions, including culture medium with Nitzschia closterium f.minutissima or Navicula, natural seawater and sterilized natural seawater. Nitzschia closterium f.minutissima and barnacle cyprid were selected to explore the adhesion performance of the pure Ti polarized at different potentials. The results showed that the surface film of Ti sample polarized at 0.5 VSCE was very stable in all the solutions, but the surface film of Ti sample polarized at -0.8 VSCE was not stable in the early stage, and it would continue to grow under open circuit potential and gradually become stable after a long time immersion. Corrosion did not occur in all samples after 143 days of immersion. Biological adhesion test showed that lots of microalgae bodies and their metabolites covered life activity, and adhered to the two kinds of Ti sample surface after 143 days of immersion. These biological fouling attachments on the surface of Ti sample could be easily removed by washing with deionized water, implying that the adhesion strength of these attachments was relatively weak. No obvious damage was observed on the surface of Ti samples. This indicated that the two different titanium surface states have limited influence on the fouling of microalgae after a long time. However, the Ti sample polarized at 0.5 VSCE had a lower Nitzschia closterium f.minutissima adhesion density and barnacle cyprids adhesion rate in the first three days, due to the differences in the composition and hydrophilicity of the two surface films. These results indicating that the antifouling property of Ti may be affected by different polarization treatments at the initial stage, while this effect was limited in a long-term immersion.

Key words: pure titanium; surface film; seawater; electrochemical behavior; biofouling

/

| 〈 |

|

〉 |