铝合金表面改性对有机涂层附着力的影响及腐蚀防护性能研究

收稿日期: 2021-02-01

修回日期: 2021-03-04

网络出版日期: 2021-03-27

基金资助

国家自然科学基金项目(21621091);国际科技合作专项(2014DFG52350)

Effect of Aluminum Alloy Surface Modification on Adhesion of the Modified Polyurethane Coating and Its Corrosion Protective Performance

Received date: 2021-02-01

Revised date: 2021-03-04

Online published: 2021-03-27

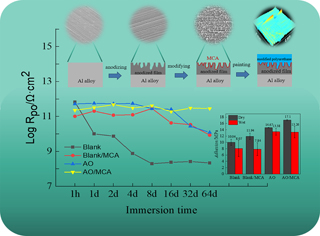

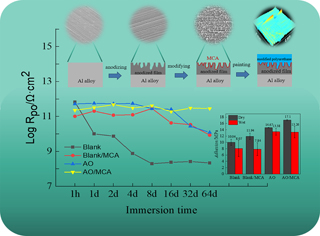

利用电化学阻抗(EIS)、扫描微参比技术(SRET)、接触角、粗糙度、附着力、盐雾等测试方法,研究了铝合金阳极氧化与贻贝黏附蛋白(MAP)/CeO2/硅烷γ-APS(MCA)表面复合修饰的腐蚀防护性能以及对改性聚氨酯涂层附着力和耐蚀性的影响。结果表明,MCA复合膜可抑制铝合金的腐蚀,并具有一定的自修复功能;阳极氧化和MCA表面复合修饰可为铝合金提供有效的早期腐蚀防护作用,且能提高铝合金表面粗糙度和润湿性,显著提升改性聚氨酯涂层在铝合金表面的附着力和耐蚀性,因而结合改性聚氨酯涂层和表面复合修饰可实现对铝合金长期有效的腐蚀防护。

况先银 , 金少强 , 曹艳辉 , 张艳梅 , 董士刚 , 朱龙晖 , 林理文 , 林昌健 . 铝合金表面改性对有机涂层附着力的影响及腐蚀防护性能研究[J]. 电化学, 2021 , 27(6) : 624 -636 . DOI: 10.13208/j.electrochem.210127

The ordinary organic coatings on aluminum alloy usually encounter a problem of low adhesion to the substrate, which results in destruction and failure of the long-term protective performance of the anticorrosion systems. The surface modification of aluminum alloy is able to enhance the adhesion of organic coating on aluminum alloys, and to improve their protective performance. In this work, a combined surface modification of anodic oxidation and mussel adhesion protein/CeO2/3-aminopropyltriethoxysilane composite film (MCA) was developed on the aluminum alloy. The adhesion of modified polyurethane coated on the treated aluminum alloy and its corrosion protective performance were evaluated comprehensively by using contact angle, adhesion strength, electrochemical impedance spectroscopy (EIS), and scanning reference electrode technique (SRET). The measurements of EIS and SRET demonstrated that the MCA composite film on anodic oxidized Al possessed self-healing function and provided effective protection against early corrosion of aluminum alloy. The pull-off test showed that both anodic oxidation treatment and MCA composite film modification were able to increase the adhesion of modified polyurethane coating on aluminum alloy, and their combined action were supposed to remarkably enhance the adhesion strength up to 17.1 MPa. The reason for the improvement of adhesion was that the anodic oxidation treatment and MCA composite film modification could improve the surface roughness of aluminum alloy, and enhance the surface wettability and surface polarity, which is beneficent to enhance the bonding of the modified polyurethane coating to aluminum alloy surface. The EIS results showed that no any corrosion occurred for the modified polyurethane coating on the treated aluminum alloy during 65 d immersion in 3.5wt.% NaCl solution. The impedance value in low frequency range of the modified polyurethane coating always maintained at a high order of magnitude on the aluminum alloy treated by anodic oxidation and MCA composite film modification, showing an excellent protective performance of the coating system. The evaluation of Neutral Salt Spray (NSS) indicated that the modified polyurethane coating on the treated aluminum alloy owned superior corrosion protection performance, and the adhesion strength remained 13.1 MPa and no any corrosion was found at the scratch locations even after 1200 h of salt spray testing. It was concluded that combination of anodic oxidation and MCA composite film were capable of significantly improving the adhesion of modified polyurethane coating on aluminum alloy and providing long-term effective corrosion protection for aluminum alloy.

/

| 〈 |

|

〉 |