3D NAND制程中选择性刻蚀工艺的SiO2回沾问题研究进展

收稿日期: 2020-06-11

修回日期: 2020-07-13

网络出版日期: 2020-12-02

Research Progress of SiO2 Regrowth during Selective Etching Process in 3D NAND Manufacture Procedure

Received date: 2020-06-11

Revised date: 2020-07-13

Online published: 2020-12-02

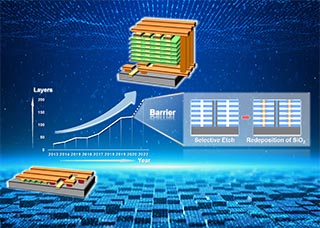

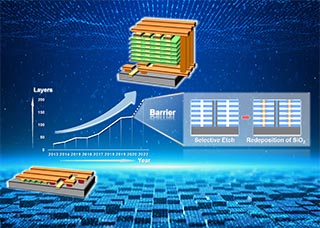

作为半导体市场中主要存储芯片之一,NAND已从2D发展到3D。3D NAND的立体存储结构提高了芯片容量、性能和可靠性。在3D NAND的交替堆栈结构中,需通过氮化-物氧化物的选择性刻蚀获得层间介质层,堆栈层数越多,芯片性能越好,但高层堆栈的刻蚀均匀性也更难保持,此时易出现SiO2在氧化层端头再沉积的回沾现象,层间结构被破坏,影响器件性能。要达到更高层数必须减少回沾,探究该过程及其影响因素成为关键所在。本文综述了3D NAND制程中氮化硅选择性刻蚀工艺的发展现状和现有研究成果,强调了控制硅含量对防止回沾的重要性,介绍了相关理论模型,提供模拟预测。为深入分析其中的化学反应,本文对相关的SiO2溶液化学进行了概述,总结了聚硅酸形成的影响因素,强调胶凝曲线能反应其聚合行为,据此可研究怎样通过影响硅酸聚合行为或聚硅酸在氧化层表面的沉积行为来防止回沾,以对未来研究起到理论指导作用.

周紫晗 , 吴蕴雯 , 李明 , 王溯 . 3D NAND制程中选择性刻蚀工艺的SiO2回沾问题研究进展[J]. 电化学, 2021 , 27(1) : 26 -34 . DOI: 10.13208/j.electrochem.200610

As one of the most significant memory chips in semiconductor market, NAND has been developed from two-dimension (2D) to three-dimension (3D). Due to the three-dimensional memory structure of 3D NAND, the capacity density, read-write speed and reliability of memory chips have been greatly improved, as well as the reduction of power dissipation. It is by nitride-oxide selective etching process in the alternate stacked structure of 3D NAND that the inter-dielectric layers can be obtained. The more stack layers, the better performance of chips will be. Meanwhile, however, silicon dioxide (SiO2) would regrow on the corner of oxide layers, the phenomenon called regrowth, which directly makes damage to the stack structure. If the deposition is so thick that becomes adhesive together, the stack structure will collapse, severely affecting the performance of devices. Preventing SiO2 regrowth is imperative for higher stacked layers, meaning that the key point is to figure out the specific process of regrowth and its impact factors. Due to the rapid development of this field, the existing information is such a mess that there is a lack of sorted information and systematic research dealing with the problem of regrowth. This paper briefly reviewes developing situation and existing research results of silicon nitride selective etching process in 3D NAND manufacture procedure, with emphases in the significance of controlling silicon concentration to avoid regrowth. Furthermore, relative theoretical models are introduced to provide simulation and prediction for regrowth process. In order to analyze the chemical reaction in regrowth, this paper summarizes the relative solution chemistry of silica and the impact of polysilicic acid formation, and suggests that the gel curve can reflect its aggregation behavior. Accordingly, researches on how to avoid regrowth can be guided theoretically by discovering the influence factors of silicic acid aggregation or the deposition behaviors of polysilicic acid on oxide layers.

Key words: semiconductor memory; 3D NAND; etching; silicon nitride; silica; silicic acid

/

| 〈 |

|

〉 |