BC/CoNi2S4@PPy柔性复合电极材料的制备及电化学性能

收稿日期: 2020-06-30

修回日期: 2020-09-07

网络出版日期: 2020-11-03

基金资助

国家重点基础研究发展计划项目(2014CB239702);国家自然科学基金项目(21676082)

Preparations and Electrochemical Properties of BC/CoNi2S4@PPy Flexible Composites for Supercapacitors

Received date: 2020-06-30

Revised date: 2020-09-07

Online published: 2020-11-03

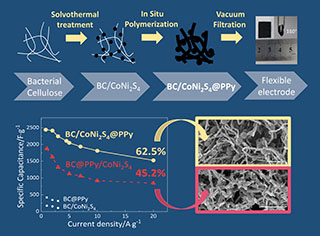

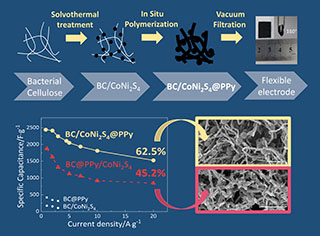

本文采用溶剂热、原位聚合和真空抽滤相结合的方法制备了用于超级电容器的细菌纤维素/镍钴硫化物/聚吡咯(BC/CoNi2S4@PPy)柔性电极材料,通过X射线衍射、场发射扫描电镜、红外光谱、氮气吸脱附、拉伸强度和接触角表征了材料的形貌结构、组成、机械性能和亲水性,并采用循环伏安法和恒电流充放电测试了复合材料的电化学性能。结果表明,表面含氧官能团丰富的BC纤维网络结构对氧化还原活性物质CoNi2S4的生长和导电聚合物PPy的分布具有引导作用,CoNi2S4均匀分布在BC网络中,且PPy均匀包覆在BC纤维和CoNi2S4纳米球表面构成具有丰富孔隙结构的三维导电网络,使得该复合材料具有较好的机械性(抗拉强度达28.0±0.1 MPa)、亲水性(对6 mol·L-1 KOH的瞬间接触角为43.6°)及良好的导电性。该电极材料在1 A·g-1下比电容高达2670 F·g-1,充放电循环10000次后比电容的保持率为82.73%,且经1000次反复弯曲后电化学性能保持不变。此外,将其与活性炭组成的非对称超级电容器,在1 A·g-1下比电容为1428 F·g-1,最高能量密度和功率密度分别达49.8 Wh·kg-1和741.8 W·kg-1。

彭思源 , 杨实润 , 周静红 , 隋志军 , 章涛 , 石易 , 周兴贵 . BC/CoNi2S4@PPy柔性复合电极材料的制备及电化学性能[J]. 电化学, 2021 , 27(1) : 14 -25 . DOI: 10.13208/j.electrochem.200630

Flexible supercapacitor is one of the most promising energy storage devices for portable and wearable electronic products due to its advantages of high power density, fast charging and long cycle life. Therefore, self-supporting flexible electrode materials with high performance have attained more and more attention both in academia and in industry recently. In this work, using bacterial cellulose (BC) as a flexible substrate, the bacterial cellulose/nickel-cobalt sulfide@polypyrrole (BC/CoNi2S4@PPy) flexible composites with three-dimensional porous network and good conductivity were prepared by a combined solvothermal-in-situ polymerization-vacuum filtration method. The samples were characterized by X-ray diffraction, field emission scanning electron microscopy, Fourier transform infrared spectrometry, N2 physisorption, tensile strength and contact angle measurements. Their electrochemical performances were tested by cyclic voltammetry, galvanostatic charge/discharge testing and electrochemical impedance spectroscopy. The results show that the three-dimensional porous network of BC fibers with rich oxygen-containing surface groups play a guiding role in the growth of the redox active material CoNi2S4 and the distribution of conductive polymer PPy, resulting in uniformly distributed CoNi2S4 nanospheres in the network of BC fibers, both coated evenly with a layer of conductive PPy. The resulting BC/CoNi2S4@PPy composites, a three-dimensional conductive network with high porosity, displayed good mechanical property (tensile strength up to 28.0±0.1 MPa), hydrophilicity (the instantaneous contact angle in 6 mol·L-1 KOH is 43.6°), as well as excellent electrochemical performance. The specific capacitance of the flexible BC/CoNi2S4@PPy was 2670 F·g-1 at 1 A·g-1 in a three-electrode system, and retained 82.7% after 10000 charge and discharge cycles. In addition, the electrochemical performance remained unchanged after 1000 times of repeated bending. In an asymmetric supercapacitor composed of BC/CoNi2S4@PPy and activated carbon, the area specific capacitance was 1428 F·g-1 at 1 A·g-1. The asymmetric supercapacitor achieved the maximum energy density of 49.8 Wh·kg-1 and power density of 741.8 W·kg-1.

/

| 〈 |

|

〉 |