电沉积法制备石墨烯纸-金属复合材料的初步研究

收稿日期: 2020-06-13

修回日期: 2020-07-20

网络出版日期: 2020-09-23

基金资助

国家自然科学基金青年项目(11505195);国家自然科学基金青年项目(51704021);中央高校基本科研业务费(RF-TP-20-004A3);中央高校基本科研业务费(FRF-TP-19-030A2);中央高校基本科研业务费(FRF-TP-16-079A1)

A Preliminary Study on Graphene Film-Metal Composites Prepared by Electrodeposition

Received date: 2020-06-13

Revised date: 2020-07-20

Online published: 2020-09-23

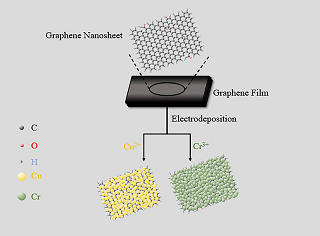

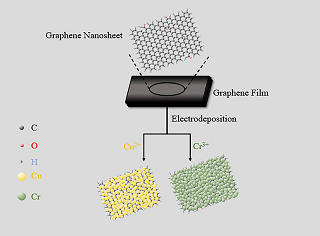

石墨烯纸具有优良的导电导热性能,但强度和硬度较低。为了获得良好的综合力学性能以提高石墨烯纸的实用价值,本文提出了制备石墨烯纸-金属复合材料的构想,从实验上初步研究了电沉积法制备石墨烯纸-金属复合材料的可行性,并探究了石墨烯纸与电沉积金属界面结合情况。采用两种常见镀层金属Cu、Cr,在实验室使用电沉积法制备了石墨烯纸-Cu,石墨烯纸-Cr两种复合镀层材料。利用扫描电镜对复合材料的表面形貌和横截面进行了表征,结果显示石墨烯纸-Cr复合材料的界面结合相对紧密。本文首次将二维错配度应用到石墨烯纸与金属镀层界面结合力分析中,通过计算分析,常温下C 的(0001)面与Cr的(110)面的二维错配度为7.26%,晶格匹配度良好. 随温度升高,C-Cr界面错配度值减小,即晶格匹配度增加,另外C-Cr二元相图显示C与Cr发生反应生成的碳化物将进一步增强其界面结合。

刘双娟 , 王海静 , 郭靖 , 王鹏程 , 周昊 , 孟才 , 郭汉杰 . 电沉积法制备石墨烯纸-金属复合材料的初步研究[J]. 电化学, 2021 , 27(4) : 396 -404 . DOI: 10.13208/j.electrochem.200614

Graphene film (GF) has excellent electrical and thermal conductivity, but low strength and hardness. In order to obtain good comprehensive mechanical properties to improve the practical value of GF, the concept of preparing GF-metal composite materials was proposed. This work was conducted to preliminarily study the feasibility of using electrodeposition method to prepare GF-metal composites. Two kinds of composites, GF-Cu and GF-Cr, were successfully prepared by using GF as the cathode, and pure Cu and DSA (Dimensionally Stable Anode) as the anodes, respectively, with applying DC power externally. Employing certain electrochemical parameters, the cation in the electrolyte moved towards the cathode directionally. Meanwhile, the interface bonding between GF and electrodeposited metals was investigated. The surface morphology and cross-section characterization of the composites by scanning electron microscopy showed that the interface bonding of the GF-Cr composite was tighter than that of the GF-Cu composite. In addition, two-dimensional disregistry analyses were performed for the GF and metals coating interface bonding. Through calculation and analysis, the disregistry of the (110) surface on Cr is 7.26%, while that of the (111) surface on Cu is 31.92% at the(0001) surface of C and at room temperature, indicating that the lattice matching degree of C and Cr is better than that of C and Cu, which is consistent with the experimental results. As the temperature increased, the disregistry value of C-Cr interface decreased, that is, increasing the temperature is conducive to the increase of lattice matching of both. The C-Cr binary phase diagram also showed that the carbide generated by the reaction of C and Cr would further enhance the interface bonding. The effect of heating on the C-Cu interface bonding was more complicated. The results of heat treatment experiments showed that the heating increased the diffusion distance of C element to the copper coating, while the disregistry value of C-Cu interface increased with the increase of temperature. However, the interface bonding of GF and Cu still needs to be improved.

Key words: electrodeposition; graphene film; two-dimensional disregistry; Cu; Cr

/

| 〈 |

|

〉 |