高容量材料Si@CPZS在锂离子电池中的储锂性能研究

a. 共同第一作者.

收稿日期: 2019-02-26

修回日期: 2019-03-22

网络出版日期: 2019-03-29

基金资助

国家自然科学基金项目(21573265);国家自然科学基金项目(21805292)

版权

Lithium Storage Performance of High Capacity Material Si@CPZS in Lithium Ion Batteries

Received date: 2019-02-26

Revised date: 2019-03-22

Online published: 2019-03-29

Copyright

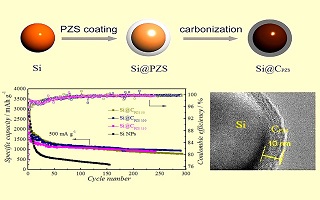

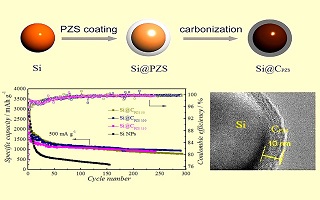

本文通过简单的溶胶-凝胶法以聚环三磷腈-4,4'-磺酰基二苯酚聚合物(PZS)为碳源通过在硅纳米颗粒表面包覆碳层,成功构筑了核壳结构的Si@C复合材料. 通过对不同厚度碳层包覆的Si@CPZS的储锂性能进行研究,发现当硅表面PZS衍生碳厚度为10 nm时具有最佳的储锂性能,且经过长达290圈的循环后容量仍然保持在940 mAh·g-1,并且利用X射线衍射图谱、热重、比表面孔径测定仪及透射电镜等分析手段对样品进行了结构和组分分析. 本文进一步将Si@CPZS复合材料作为石墨的添加剂,结果表明30%的Si@CPZS复合材料可将石墨负极的容量提升至700 mAh·g-1.

张庆暖 , 张芳芳 , 李红霞 , 杨兵军 , 李小成 , 杨娟 . 高容量材料Si@CPZS在锂离子电池中的储锂性能研究[J]. 电化学, 2020 , 26(1) : 121 -129 . DOI: 10.13208/j.electrochem.190226

Carbon layers with different thicknesses were introduced into the surfaces of silicon (Si) nanoparticles by sol-gel method using poly (cyclotriphosphazene-co-4, 4'-sulfonyldiphenol) as the carbon source. Technologies of X-ray diffraction, thermo-gravimetric analysis, Brunauer-Emmett-Teller and transmission electron microscopy were employed to analyze the structures and components of the as-prepared Si@CPZS composites. Electrochemical performance of Si@CPZS with different carbon thicknesses was studied. The results showed that Si@CPZS with carbon thickness of 10 nm possessed the best performance. Its capacity remained 940 mAh·g-1 after 290 cycles under 500 mA·g-1. As the addictive, the graphite-based anode contained 30% of Si@CPZS composite could achieve the specific capacity higher than 700 mAh·g-1.

Key words: Si@C; anode; lithium ion battery; addictive of graphite

/

| 〈 |

|

〉 |