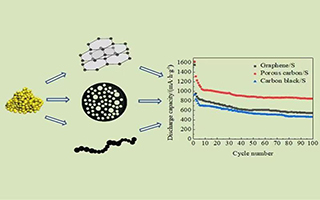

硫在不同碳载体材料中的电化学性能研究

收稿日期: 2018-12-04

修回日期: 2019-02-18

网络出版日期: 2019-12-28

基金资助

天津师范大学人才引进项目(No. 011/5RL132)资助

Electrochemical Properties of Sulfur in Different Carbon Support Materials

Received date: 2018-12-04

Revised date: 2019-02-18

Online published: 2019-12-28

张 波 , 刘 佳 , 刘晓晨 , 李德军 . 硫在不同碳载体材料中的电化学性能研究[J]. 电化学, 2019 , 25(6) : 749 -756 . DOI: 10.13208/j.electrochem.181117

/

| 〈 |

|

〉 |