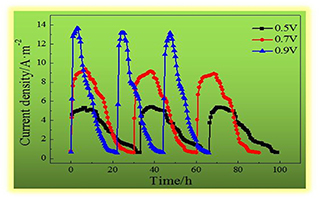

为寻找质优价廉的析氢催化剂,本研究以废旧金属网为单室微生物电解池(MEC)阴极,在不同外加电压下考察其制氢性能. 同时利用16S rDNA扩增测序技术分析原接种污泥、MFC和MEC阳极微生物的菌落特点. 实验结果表明,随着外加电压的增大,MEC产生的最大电流密度和周期运行时间分别呈现增大和缩短的趋势. 外加0.7 V电压时,废旧金属网阴极MEC的氢气产率和电能回收率分别达到0.330±0.012 m3H2·m-3·d-1和177.0±5.6%,远高于0.5 V时的数值,与0.9 V时相差不大. 废旧金属网阴极MEC的产氢能力可以和Pt/C阴极MEC相媲美,且具有良好的运行稳定性. 16S rDNA扩增测序结果显示培养环境对微生物的富集与淘汰有很大影响. 在外加电场环境中MEC阳极的优势菌落地杆菌属(Geobacter)得到很大程度富集,相对丰度高达79.4%以上.

In order to find high quality and low price hydrogen catalyst, a scrap metal net was used as single-chamber microbial electrolytic cell (MEC) cathode, and its hydrogen production performance was investigated at different applied voltages. Meanwhile, the microbial community structures of original aerobic activated sludge, MFC and MEC anode microbes were analyzed by 16S rDNA amplicon sequencing technology. As the applied voltage increased, the maximum current density was increased and the running time was shortened. At an applied voltage of 0.7 V, the hydrogen production and electrical energy efficiency obtained with scrap metal mesh cathode MEC were, respectively, 0.330±0.012 m3H2·m-3·d-1 and 177.0±5.6%, which were much higher than those at 0.5 V, but similar to those at 0.9V. The performance of waste metal mesh cathode MEC was comparable to that of Pt/C cathode MEC, and had good durability. The results of 16S rDNA amplicon sequencing showed that the culture environment had a great influence on the enrichment and elimination of microorganisms. Geobacter, the dominant bacterium of MEC anode, was extremely enriched in the applied electric field environment with a relative abundance of more than 79.4%.