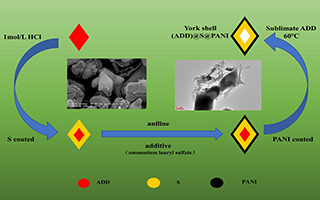

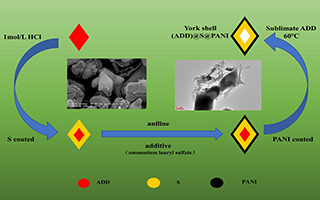

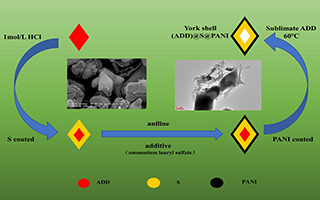

本文首次提出采用升华物质为模板,制备聚苯胺包覆的中空硫电极材料. 首先通过Na2S2O3和稀HCl反应,在具有升华特性的ADD(2,4,6-三异丙基-1,3,5-三氧杂环己烷)微粒表面沉积一层S,然后在S的表面再沉积聚苯胺包覆层. 在经60 oC干燥12小时后,其中的ADD自然挥发,得到聚苯胺壳体包覆的中空硫复合物. SEM、TEM和TG分析表明,制得的聚苯胺包覆中空硫的粒径约为2 μm,硫含量为61.1%. 在500 mA·g-1充放电电流下,首次放电比容量为776.2 mAh·g-1,库仑效率为95.9%. 100次充放电循环后,放电比容量为524.7 mAh·g-1. 由于聚苯胺包覆物的聚苯胺膜具有抑制聚硫锂向外的扩散作用,以及包覆物中的空间对放电时S的膨胀具有缓冲作用,聚苯胺包覆中空硫粉末的放电比容量和充放电稳定性均明显高于未包覆聚苯胺的中空硫和化学制备的硫. 这种制备导电聚合物包覆中空硫的新方法具有操作简单、成本低廉的优点,有进一步发展的前景.

李张峰, 王晓锐, 田文生, 杨津泽, 张 平, 马丽萍, 陈 阳, 崔晓莉, 江志裕

. 利用升华物质2,4,6-三异丙基-1,3,5-三氧杂环己烷作模板剂制备聚苯胺包覆的中空硫电极材料[J]. 电化学, 2019

, 25(6)

: 645

-650

.

DOI: 10.13208/j.electrochem.180530

An advance method for preparing polyaniline-coated hollow sulfur material using sublimate material ADD(2,4,6-tri(propan-2-yl)-1,3,5-trioxane) as a template was developed for lithium-sulfur battery. At first, the smashed ADD particles were coated by a sulfur layer through the reaction of Na2S2O3 with diluted HCl. Then polyaniline layer was coated again on the surface of sulfur layer through the reaction of aniline with (NH4)2S2O8. After being dried at 60 oC for 12 h, the ADD in such a composite evaporated totally, and resulted in the formation of polyaniline-coated hollow sulfur composite. The SEM, TEM and TG measurements showed, that the particle size of as prepared polyaniline-coated hollow sulfur composite was about 2 μm, and the content of sulfur in the composite was 61.1%. The first discharge capacity was 776.2 mAh·g-1 with a coulombic efficiency of 95.9%, at charge-discharge current of 500 mA·g-1. After 100 cycles, the discharge capacity remained 524.7 mAh·g-1. Because the polyaniline layer could inhibit the diffusion of polysurfides to outside of membrane, the hollow space in the core could buffer the volume change of sulfur during cycling. The discharge capacity and the charge-discharge stability of polyaniline-coated hollow sulfur were much higher than those of hollow sulfur without coating polyaniline, as well as those of chemical prepared sulfur. This new method for preparing polyaniline-coated hollow sulfur material is simple, low cost, and may have a promising prospect for the practical application.