低铂膜电极结构优化途径

收稿日期: 2018-09-05

修回日期: 2018-09-27

网络出版日期: 2018-10-12

基金资助

国家自然科学基金项目(No. 20833005,No. 20828005,No. 20921120405)资助

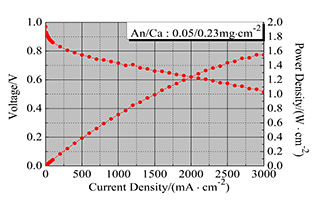

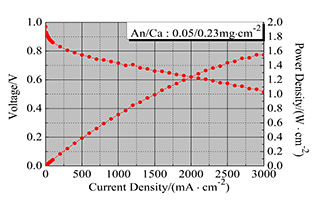

Fuel cell performance curve after MEA optimization Structural Optimization of Low Pt Membrane Electrode Assembly

Received date: 2018-09-05

Revised date: 2018-09-27

Online published: 2018-10-12

饶妍 , 李赏 , 周芬 , 田甜 , 钟青 , 宛朝辉 , 谭金婷 , 潘牧 . 低铂膜电极结构优化途径[J]. 电化学, 2018 , 24(6) : 677 -686 . DOI: 10.13208/j.electrochem.180843

/

| 〈 |

|

〉 |