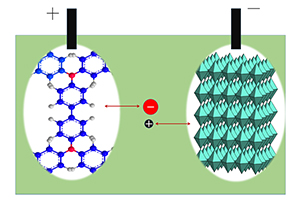

由于高安全、高功率和超长循环寿命等优点,钛酸锂负极材料近年来得到了广泛关注,基于钛酸锂负极的高性能超级电池电容器和锂离子电池也成为近年来的研究热点. 本文采用化学氧化法制备了有机物正极材料聚三苯胺,并通过经典的电化学测试方法研究了其储能机理及相应的电极动力学过程. 研究结果表明,该有机物正极的储能机制主要是基于阴离子的吸脱附反应,并表现出85 mA·g-1的可逆容量,且其动力学过程不受扩散控制,属于典型的赝电容行为. 将该正极与钛酸锂负极结合构成了新型的电池电容体系,并对其电化学性能进行了研究,结果表明该体系具有高功率特性,且能量密度高于传统的混合型超级电容器. 此外,本文还对该有机物正极的不足和实际应用中所面临的挑战做了初步分析.

Owing to its high safe, high rate and long life characteristics, lithium titanate (Li4Ti5O12) anode material has attracted extensive attention in recent years, and many efforts are being made to develop the Li4Ti5O12 based high performance hybrid supercapacitors and Li-ion batteries. Herein, we prepared the organic cathode material polytriphenylamine (PTPAn) through chemical oxidation and polymerization of triphenylamine (TPAn), and investigated its charge storage mechanism and electrode kinetics withthe typical electrochemical methods in an organic electrolyte. It was demonstrated that the PTPAn exhibited the reversible capacity of 85 mA·g-1. The charge storage depended on the reversible adsorption/desorption of anion, which is not controlled by the diffusion process, and thus, can be considered as the pseudocapacitive behavior. Then, the PTPAn cathode was coupled with the Li4Ti5O12 anode to form a hybrid capacitor/battery system with high power and improved energy density. Finally, the inherent drawback and the challenge for practical application of such an organic cathode are briefly discussed.