金属线电极分形生长的模拟

收稿日期: 2017-07-11

修回日期: 2017-09-06

网络出版日期: 2017-09-11

基金资助

国家自然科学基金青年基金项目(No. NSFC51604180)、山西省应用基础研究计划项目面上青年基金项目(No. 201701D221036)、山西省高等学校大学生创新创业训练项目(No. 201614101009)、太原工业学院教学改革研究项目(No. 2015YJ08)及太原工业学院青年学术带头人支持计划资助

Simulation of Fractal Growth on Metal Wire Electrode

Received date: 2017-07-11

Revised date: 2017-09-06

Online published: 2017-09-11

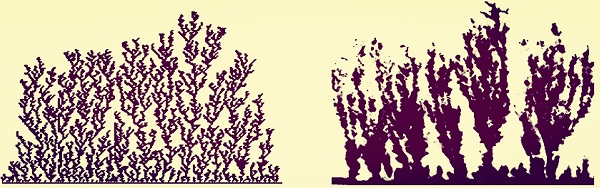

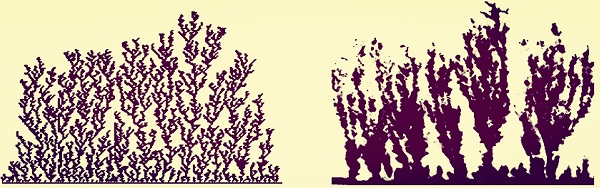

电沉积金属过程中,阴极沉积的金属边缘会出现包括枝晶生长在内的许多复杂形态,这会严重影响电沉积产品的质量和加工过程中的电流效率. 对枝晶分形生长的过程以及形貌进行研究,可以实现对沉淀物的可控生长. 本研究使用Python和Matlab软件相互结合,基于扩散限制凝聚(DLA)模型,建立平行线电极电沉积的模型. 通过分析不同粒子数、沉积概率、电极间距、运动步长、定向漂移条件下的分形生长的变化规律,以及模拟参数与实际电沉积因素对分形生长影响的内在联系,发现只要合理控制模拟的粒子数、沉积概率、线电极间距、运动步长、定向漂移概率参数即可与实际电化学体系的浓度和沉积时间、还原概率、两极间距、温度和电压、电极的相对位置和形状一一对应,从而模拟得到跟实际电沉积接近的分形图,最终可实现对分形生长的可控操作,对分形生长在工业电沉积等方面应用有很大的意义.

丁莉峰 , 毛沛元 , 程军 , 牛宇岚 , 文宇浩 , 程玮 . 金属线电极分形生长的模拟[J]. 电化学, 2018 , 24(3) : 285 -291 . DOI: 10.13208/j.electrochem.170711

During processes of metal electrodepostion, there exist many complex morphological forms such as dendritic growing in the cathode deposited metal edge, which will seriously affect the quality of the electrodeposited product and current efficiency during machining. Investigations on dendritic crystal growing process and morphology could help controlling growth of electrolysis precipitate. In this work, Python and Matlab softwares were used, and the model of parallel electrode electrodeposition was established based on the diffusion-limited aggregation (DLA) model. By analyzing the law of fractal growth at different conditions of the particles number, probability, electrode spacing, the movement step length and orientation drift, and the inner link between simulation parameters and practical factors that affect fractal growth of electrodeposition, it was found that the simulation results can match the actual parameters by controlling the simulation parameters such as particles number, wire electrode spacing, movement step length and orientation drift probability. The inner connection between simulated parameters and actual electrodeposition factors is discussed. Finally, the specific electrodeposition experiments can be simulated by changing the computer variables, which is controllable and crucial to applying the fractal growth to industry electrolysis.

Key words: wire electrode; fractal growth; electrodeposition; fractal dimension

/

| 〈 |

|

〉 |