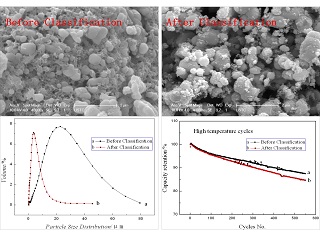

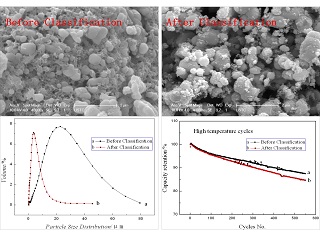

分级过程对LiFePO4/C电池性能的影响

收稿日期: 2016-09-30

修回日期: 2017-01-14

网络出版日期: 2017-06-08

基金资助

安徽省科技攻关项目(No. 1501021011)资助

Effects of jet milling and classifying process on the performance of LiFePO4/C in full batteries

Received date: 2016-09-30

Revised date: 2017-01-14

Online published: 2017-06-08

刘兴亮 , 杨茂萍 , 汪伟伟 , 曹勇 . 分级过程对LiFePO4/C电池性能的影响[J]. 电化学, 2017 , 23(6) : 661 -666 . DOI: 10.13208/j.electrochem.160930

/

| 〈 |

|

〉 |