[1] Parmeggiani C, Cardona F. Transition metal based catalysts in the aerobic oxidation of alcohols[J]. Green Chem- istry, 2012, 14(3): 547-564.

[2] Enache D I, Edward J K, Landon P, et al. Solvent-free oxidation of primary alcohols to aldehydes using Au-Pd/TiO2 catalysts[J]. Science, 2006, 311(5759): 362-365.

[3] Liu J, Yang H Q, Kleitz F, et al. Yolk-shell hybrid materials with a periodic mesoporous organosilica shell: Ideal nanoreactors for selective alcohol oxidation[J]. Advanced Functional Materials, 2012, 22(3): 591-599.

[4] Watanabe H, Asano S, Fujita S, et al. Nitrogen-doped, metal-free activated carbon catalysts for aerobic oxidation of alcohols[J]. ACS Catalysis, 2015, 5(5): 2886-2894.

[5] Adam W, Gelalcha F G, Saha-Möller C R, et al. Chemoselective C-H oxidation of alcohols to carbonyl compounds with iodosobenzene catalyzed by (salen) chromium complex[J]. The Journal of Organic Chemistry, 2000, 65 (7):1915-1918.

[6] Menger F M, Lee C. Synthetically useful oxidations at solid sodium permanganate surfaces [ J ] . Tetrahedron Letters ,1981, 22(18): 1655-1656.

[7] Sato K, Aoki M, Takagi J , et al. Organic solvent- and halide-free oxidation of alcohols with aqueous hydrogen peroxide [J]. Journal of the American Chemical Society,1997, 119(50): 12386-12387.

[8] Abad A, Almela C, Corma A, et al. Efficient chemoselective alcohol oxidation using oxygen as oxidant. Superior performance of gold over palladium catalysts[J]. Tetrahedron, 2006, 62(28): 6666-6672.

[9] Teng Y, Song L X, Wang L B, et al. Face-raised octahedral Co3O4nanocrystals and their catalytic activity in the selective oxidation of alcohols[J]. The Journal of Physical Chemistry C, 2014, 118(9): 4767-4773.

[10] Zhu J, Kailasam K, Fischer A, et al. Supported cobalt oxide nanoparticles as catalyst for aerobic oxidation of alcohols in liquid phase[J]. ACS Catalysis, 2011, 1(4): 342-347.

[11] Kowal A, Port S N, Nichols R J. Nickel hydroxide electrocatalysts for alcohol oxidation reactions: An evalua- tion by infrared spectroscopy and electrochemical methods[J]. Catalysis Today, 1997, 38(4):483-492.

[12] Li J, Li J, Wang H, et al. Electrocatalytic oxidation of n-propanol to produce propionic acid using an electro- catalytic membrane reactor[J]. Chemical Communications, 2013, 49(40): 4501-4503.

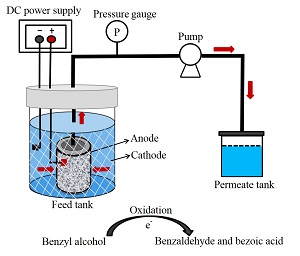

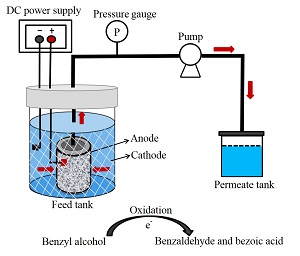

[13] Tian W J(田文杰)Wang H(王虹), Yin Z(尹振), et al.Preparation of nano-manganite loaded titanium electo- catalytic membrane for the catalytic oxidation of benzyl alcohol[J]. Acta Physico-ChimicaSinica(物理化学学报),2015, 31(8): 1567-1574.

[14] Fang X, Yin Z, Wang H, et al. Controllable oxidation of cyclohexane to cyclohexanol and cyclohexanone by a nano-MnOx/Ti electrocatalytic membrane reactor[J]. Journal of Catalysis, 2015, 329: 187-194.

[15] Wöltinger J, Drauz K, Bommarius A S. The membrane reactor in the fine chemicals industry[J]. Applied Catalysis A: General, 2001, 221(1): 171-185.

[16] Ketchie W C, Fang Y L, Wong M S, et al. Influence of gold particle size on the aqueous-phase oxidation of carbon monoxide and glycerol[J]. Journal of Catalysis, 2007, 250(1): 94-101.

[17] Wang H, Wang H, Li J, et al. An electrocatalytic reactor for the high selectivity production of sodium 2, 2, 3, 3-tetrafluoropropionate from 2, 2, 3, 3-tetrafluoro-1-propanol [J]. Electrochimica Acta, 2014, 123: 33-41.

[18] Niu D F(钮东方), Yu C K(俞程凯), Zhang X S(张新胜).Preparation of benzoquinone from phenol by electrooxidation[J]. Journal of Electrochemistry(电化学), 2013, 19(5): 477-481.

[19] Liu H, Vecitis C D. Reactive transport mechanism for organic oxidation during electrochemical filtration: Mass-transfer , physical adsorption , and electron-transfer [J]. Journal of Physical Chemistry C, 2012, 116(1):374-383.

[20] Camara G A, Iwasita T. Parallel pathways of ethanol oxidation: The effect of ethanol concentration[J]. Journal of Electroanalytical Chemistry, 2005, 578(2): 315-321.

[21] Enache D I, Edwards J K, Landon P, et al. Solvent-free oxidation of primary alcohols to aldehydes using Au-Pd/TiO2 catalysts[J]. Science, 2006, 311(5759): 362-365.

[22] Dijksman A, Marino-González A, Payeras A M I, et al. Efficient and selective aerobic oxidation of alcohols into aldehydes and ketones using ruthenium/TEMPO as the catalytic system[J]. Journal of the American Chemical Society,2001, 123(28): 6826-6833.