激光刻蚀模板中电沉积特殊结构CIGS薄膜

收稿日期: 2017-04-18

修回日期: 2017-05-04

网络出版日期: 2017-05-08

基金资助

国家自然科学基金项目(No. 51474080)资助

Electrodeposition of CIGS Thin Film with Special Structure Using Laser Etching Template

Received date: 2017-04-18

Revised date: 2017-05-04

Online published: 2017-05-08

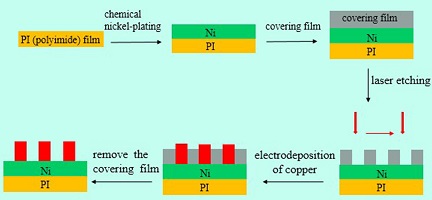

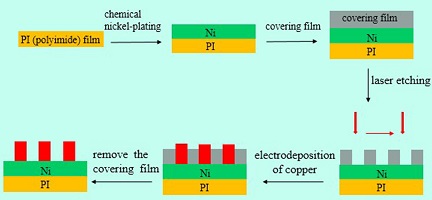

本文利用激光刻蚀模板,在水溶液中电沉积制备金属铜薄膜,讨论了温度、电流、硫酸铜浓度对薄膜形貌的影响. 采用SEM对制备的铜薄膜进行表征,结果表明在沉积温度为30 ℃,沉积电流为4 A·dm-2(表观工作电流密度),硫酸铜浓度在20 ~ 50 g·L-1的水溶液中电沉积可以得到中空馒头状和开口碗状结构的铜薄膜. 利用激光刻蚀模板,在离子液体1-丁基-3-甲基咪唑三氟甲磺酸盐([BMI][TfO]) - 30 Vol%丙醇混合电解质中电沉积CIGS薄膜,研究了沉积电势、沉积时间对薄膜形貌的影响. SEM观察发现,在沉积电势为-1.8 V,沉积时间为1.5 h条件下电沉积可以得到近似柱状的簇状花束样的CIGS薄膜, 电沉积铜后再进一步电沉积CIGS,得到了均匀有序的鼓包柱状结构的Cu/CIGS复合薄膜. 用恒电势方波法对制备的薄膜真实表面积进行测试,计算结果表明,与无模板电沉积制备的CIGS薄膜相比,激光刻蚀模板法制备的Cu/CIGS复合薄膜的表面积提高了约8倍.

于金芝 , 连叶 , 张锦秋 , 杨培霞 , 安茂忠 . 激光刻蚀模板中电沉积特殊结构CIGS薄膜[J]. 电化学, 2018 , 24(1) : 4 -12 . DOI: 10.13208/j.electrochem.170446

Copper indium gallium selenide (Cu1.00InxGa1-xSe2.00, CIGS) thin film solar cells have a wide application in semiconductor thin film batteries. The CIGS absorbing layer is the key of the thin film solar cell material. Therefore, it is of theoretical and practical significance to carry out researches in CIGS thin films. In this work, the CIGS thin films with special structures were prepared by using laser etching template. The copper thin film was firstly electrodeposited in aqueous solution with Laser etching template. The influences of temperature, current and concentration of copper sulfate on morphology and structure of the thin film were studied. The results showed that a hollow steamed bun shape and open bowl structure was formed at the surface of copper thin film electrodeposited at 30 ℃ and at the apparent current density of 4 A·dm-2 in the aqueous solution with the concentrations of CuSO4·5H2O being 20 ~ 50 g·L-1. The CIGS thin films were electrodeposited by using laser etching template in the ionic liquid 1-butyl-3-methylimidazolium trifluoromethanesulfonate ([BMIm][TfO]) - 30 Vol% propyl alcohol mixed electrolyte solution at different deposition potentials, substrates and deposition time. It was demonstrated that the clusters of flowers with approximate columnar CIGS thin film could be prepared at 1.8 V for 1.5 h. Furthermore, the electrodeposition of CIGS thin films was done on the previously electrodeposited copper substrate by Laser etching template. A uniform and orderly spheroidal structure of Cu/CIGS composite film was obtained. The apparent surface area of the Cu/CIGS composite film, calculated by constant voltage square wave method, was about 8 times larger than that of the CIGS thin film prepared without using template, which greatly enhanced absorption of light on the thin film and increased the output of the carrier. Therefore, it can be expected that the CIGS thin film with globular special structure electrodeposited in ionic liquid by laser etching template may highlight the electric conversion efficiency.

Key words: electrodeposition; CIGS; laser etching; template; ionic liquid

/

| 〈 |

|

〉 |