纤维素微孔锂电隔膜的制备及性能研究

收稿日期: 2016-07-23

修回日期: 2017-03-22

网络出版日期: 2017-10-28

基金资助

大同市科技资助项目(201316);山西省科技资助项目(20140321003-05)资助

Preparation and Characterization of Cellulose Acetate-based Separator for Lithium-ion batteries

Received date: 2016-07-23

Revised date: 2017-03-22

Online published: 2017-10-28

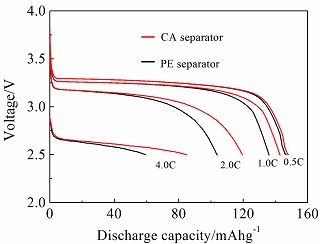

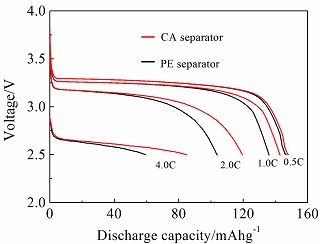

为了改善锂电隔膜的亲液性和耐高温性,以醋酸纤维素为成膜材料,利用相转化法制备了新型锂电隔膜,通过形貌和孔道结构表征、亲液性能和耐热性能测试对醋酸纤维素隔膜的基本性能进行研究,并将该隔膜装配成锂离子电池进行充放电性能测试. 结果表明,醋酸纤维素隔膜具有均匀的微孔结构,孔隙率达到65%,约为传统聚烯烃隔膜的1.5倍;纤维素材料的良好亲液性和高孔隙率结构改善了隔膜的吸液性能,其吸液率达到285%;该隔膜在150 oC、30 min的热处理条件下未发生明显的热收缩. 鉴于上述优点,相对于市售PE隔膜,醋酸纤维素隔膜所装配锂离子电池显示出更优的循环性能和倍率性能.

罗化峰 , 乔元栋 . 纤维素微孔锂电隔膜的制备及性能研究[J]. 电化学, 2017 , 23(5) : 610 -616 . DOI: 10.13208/j.electrochem.160723

/

| 〈 |

|

〉 |