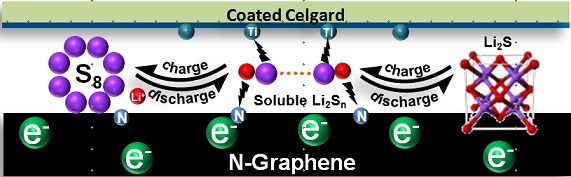

锂硫电池用碳化钛涂层隔膜性能探究

收稿日期: 2016-06-06

修回日期: 2016-08-10

网络出版日期: 2016-09-28

基金资助

国家高技术研究发展计划(863计划)(No. 2015AA034600)资助

An Investigation in the Performance of Lithium Sulfur Battery with a TiC Coated Separator

Received date: 2016-06-06

Revised date: 2016-08-10

Online published: 2016-09-28

方建华 , 曹勇 , 杨茂萍 , 郑明森 , 董全峰 . 锂硫电池用碳化钛涂层隔膜性能探究[J]. 电化学, 2017 , 23(1) : 86 -90 . DOI: 10.13208/j.electrochem.160606

Key words: Li-S battery; TiC; Coating separator

/

| 〈 |

|

〉 |