基于锂离子电池老化行为的析锂检测

收稿日期: 2016-05-27

修回日期: 2016-07-06

网络出版日期: 2016-07-14

基金资助

国家自然科学基金项目(51577104,51377097),中国博士后基金(2014M560079)资助

Lithium Plating Identification from Degradation Behaviors of Lithium-Ion Cells

Received date: 2016-05-27

Revised date: 2016-07-06

Online published: 2016-07-14

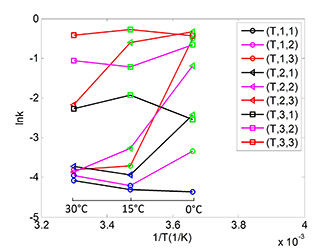

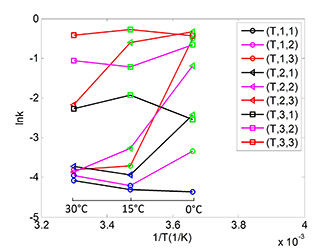

析锂会极大地影响锂离子电池的寿命和安全性,锂离子电池的析锂检测十分必要. 本文根据锂离子电池的两种主要老化机理—SEI(Solid Electrolyte Interface)膜生长和析锂对老化行为上的不同影响,基于多应力作用下的锂离子电池循环老化实验结果,提出了两种检测析锂的方法,分别为内阻-容量轨迹法和阿伦尼乌斯准则法. 两种方法的判定结果具有良好的一致性. 之后,利用微分电压法区分了电池容量损失的不同来源,并进行了电池负极片EDS(Energy Dispersive Spectrometer)能谱分析,对析锂检测方法进行了验证. 本文方法只需利用电池老化过程中可测的容量和内阻等电学量,判断方法简便,可实现非解体检测;同时,利用了单次循环的微量析锂在时间尺度上的累积,对析锂工况的辨识具有较高的敏感性. 本文方法对锂离子电池的寿命加速测试、延寿使用、安全管理等具有重要意义.

张剑波 , 苏来锁 , 李新宇 , 葛昊 , 张雅琨 , 李哲 . 基于锂离子电池老化行为的析锂检测[J]. 电化学, 2016 , 22(6) : 607 -616 . DOI: 10.13208/j.electrochem.160561

/

| 〈 |

|

〉 |