溶剂对长醇酸清漆涂层活性面积及耐腐蚀性能的影响

收稿日期: 2015-09-22

修回日期: 2015-11-26

网络出版日期: 2015-12-25

基金资助

This work was supported by Corrosion Laboratory, Chemistry department, Faculty of science, Alexandria university.

Solvent Effect on the Anticorrosive Properties and Active Coating Area of a Long Alkyd Varnish

Received date: 2015-09-22

Revised date: 2015-11-26

Online published: 2015-12-25

Supported by

This work was supported by Corrosion Laboratory, Chemistry department, Faculty of science, Alexandria university.

M. Saadawy , B.A. Abd-El-Nabey , A.Z. Gomaa , M. Ashour . 溶剂对长醇酸清漆涂层活性面积及耐腐蚀性能的影响[J]. 电化学, 2016 , 22(4) : 417 -424 . DOI: 10.13208/j.electrochem.150922

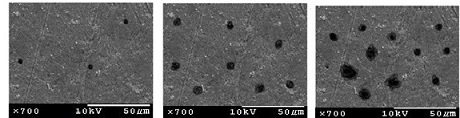

The effects of solvent nature and composition on the anticorrosive properties of a long alkyd varnish after different days of immersion in 0.5 mol•L-1 NaCl were studied using electrochemical impedance spectroscopy. The protection efficiencies of the long alkyd varnishes containing different solvents increased with increasing the volatility of solvent or the composition of a given volatile solvent, which was confirmed with the observations using scanning electron microscopy and energy-dispersive X-Ray spectroscopy. The delaminated area, the area where the organic coating is detached from the metal surface leaving it unprotected, was found to decrease by increasing the volatility of solvent.

Key words: metals; coatings; electrochemical techniques

/

| 〈 |

|

〉 |