固态氧化物阴极过程的离子扩散模型及其Ta2O5熔盐电解验证

收稿日期: 2013-09-02

修回日期: 2013-11-06

网络出版日期: 2013-11-11

基金资助

国家自然科学基金项目(No. 21173161)及教育部新世纪人才计划项目(No. NCET-11-0397)资助

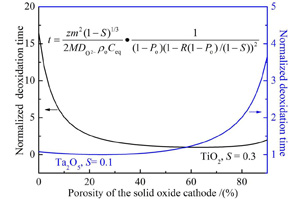

The Ionic Diffusion Model for the Solid Oxide Cathode and Its Verification by the Electrolysis of Ta2O5 in Molten CaCl2

Received date: 2013-09-02

Revised date: 2013-11-06

Online published: 2013-11-11

陈华林 , 王志勇 , 金先波 , 陈政 . 固态氧化物阴极过程的离子扩散模型及其Ta2O5熔盐电解验证[J]. 电化学, 2014 , 20(3) : 266 -271 . DOI: 10.13208/j.electrochem.130886

Key words: solid oxide; molten salt electrolysis; diffusion model; Ta2O5; Ta powder

/

| 〈 |

|

〉 |