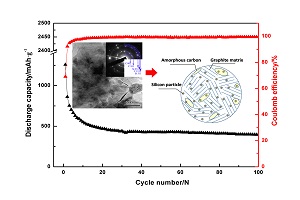

等离子体辅助球磨Si-C复合负极材料及其电化学性能研究

收稿日期: 2013-02-27

修回日期: 2013-07-01

网络出版日期: 2014-02-24

基金资助

国家自然科学基金项目(No. 51201065, No. 51231003)、中央高校基本科研业务费专项资金(No. 2012ZM0001)和广东省自然科学基金博士科研启动项目(No. S2012040008050)资助

Electrochemical Performance of Si-C Composites Prepared by Discharge-Plasma Assisted Milling

Received date: 2013-02-27

Revised date: 2013-07-01

Online published: 2014-02-24

陈宇龙 , 胡仁宗 , 刘辉 , 孙威 , 朱敏 . 等离子体辅助球磨Si-C复合负极材料及其电化学性能研究[J]. 电化学, 2014 , 20(1) : 51 -55 . DOI: 10.13208/j.electrochem.130227

Key words: lithium-ion batteries; anode; Si-C composites; discharge plasma; ball milling

/

| 〈 |

|

〉 |